We create and optimize whole packaging line automation ecosystems to deliver world-class solutions for every stage. Our highly experienced engineers at our packaging automation company challenge every assumption, while our innovative products push every boundary to ensure manufacturing consistency and sustainable growth.

Find the perfect fit with our Product Selector

Every market, every business and every project is different. So our Product Selector makes it simple to find the right solution for your needs, in just a few clicks.

Learn More >Product Assembly

Discover flexible assembly platforms that scale from your first prototype to your 50 millionth product. From pilot lines to production automation, our world-class range ensures incredible performance and user experience.

View Products

Filling & Dosing

Whether you require new dispensing technology or want to incorporate established methods to your existing application, we’re here to help you meet your filling and dosing needs.

View Products

Product Handling & Infeed

Unique products require unique solutions. Our expertly designed infeed systems are adaptable across all equipment platforms, so you can be sure that we already have the perfect solution for you.

View Products

Cartoning

Cartoning equipment is essential in ensuring that products are packaged, sealed, and delivered to customers efficiently and safely. Whether you require manually operated carton packaging machines, semi-automatic cartoners or high-speed, full packaging line automation, we can help with your cartoning equipment needs. Our world-class range of carton packaging machines and cartoning equipment includes horizontal, top load, and vertical cartoners.

View Products

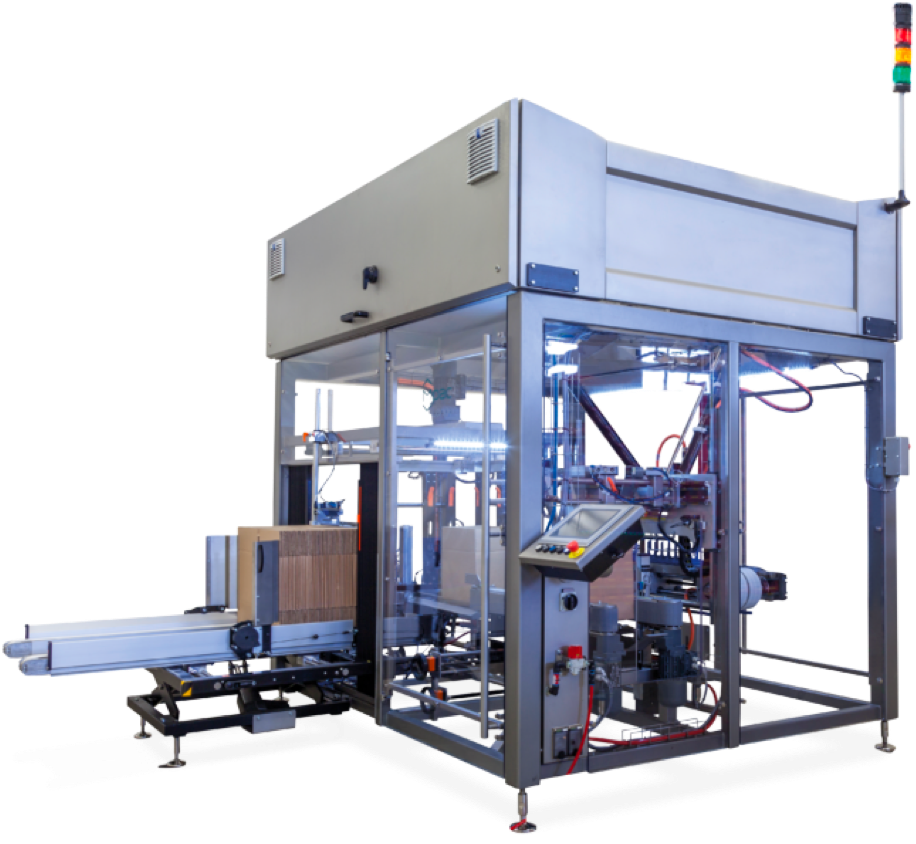

Case Packing

Have you been searching for case packer machines or box packing machines? Robust, reliable and honed over decades; our end-of-line packing and palletizing equipment handle a wide range of products to meet your bespoke needs, with fully automated robotic or combined solutions available. No more searching for case packer machines or box packing machines!

View Products

Tray Forming

With over 35 years of experience in the packaging line automation industry, we’re a packaging automation company that specializes in the conceptual development, design and manufacture of superior quality tray forming equipment, including tray formers, tray closers, flap closers, and rotary carton openers.

View Products

Palletising

Palletizing systems are essential equipment in any packaging operation. These systems handle everything from carton filling and closing to full box palletizing. Automated palletizing systems allow businesses to reduce their labor costs and improve their warehouse’s safety and efficiency. From regular slotted containers (RSC) to half slotted containers (HSC) and tray containers, all of our palletizing equipment and automatic palletizers can be integrated seamlessly into your existing packaging lines or combined with other equipment for a fully integrated palletizing system.

View Products

Our expertise provides solutions for every part of product packaging, from cartoning equipment, carton packaging machines, vertical cartoners, case packer machines, box packing machines, automatic palletizers, tray forming machines, palletizing equipment, palletizing systems, and more.

Our comprehensive range of automated systems can be tailored to your individual needs, ensuring that you get the optimal solution for your business. We’re committed to helping our customers achieve maximum productivity while reducing costs and eliminating waste – all without compromising on reliability or safety.

Packaging automation has become a vital part of the manufacturing process in today’s highly competitive business world. The implementation of automated systems, such as cartoning equipment, vertical cartoners, automatic palletizers, and packaging automation company has revolutionized the way products are packaged and shipped. These systems help packaging automation company increase efficiency, ensure consistency, and maintain quality standards, ultimately leading to sustainable growth.