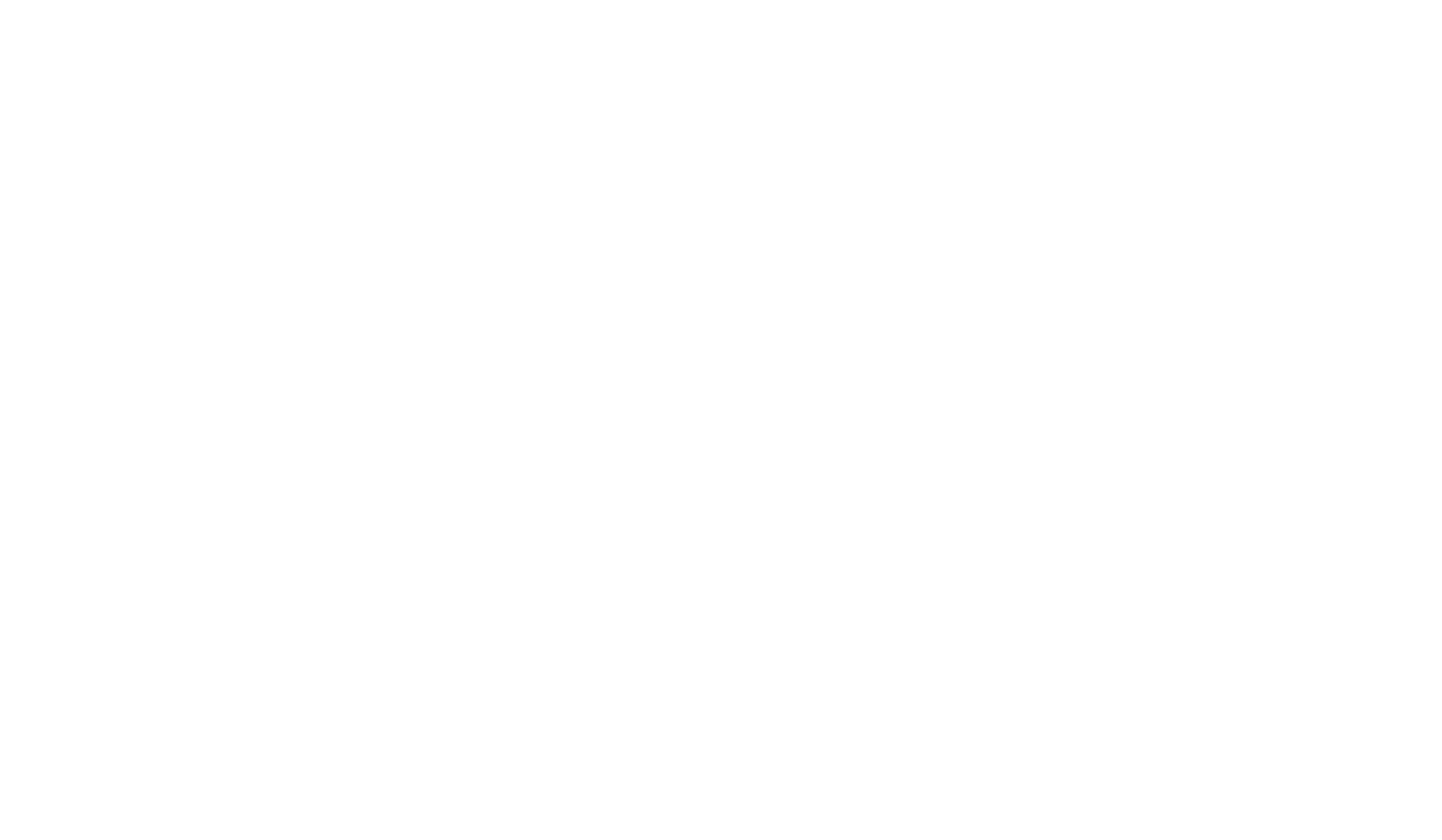

Solutions for every stage

Well-designed infeed systems carefully handle your products though the collation process, adjusted to your unique packaging requirements. Our extensive experience and world-beating infeed machine technology means we can deliver a successful solution, whatever your application.

Applications:

Our advanced product handling and infeed automation systems can handle a variety of applications, including:

- Sticks, sachets and pouches

- Bottles and jars

- Facial tissues

- Blister strips

- Bags

- Frozen food

- Flow wrap

- Trays

- Consumer goods

Industry-leading benefits

Quality & Consistency

- Gentle and precise infeed ensures delicate products remain retail-ready.

- Easy to operate, autonomous machines for consistency and less time needed for employee training.

Sustainability

- Pays for itself with up to 98% efficiency from day one, and for 25+ years.

- High energy efficiency to meet the needs of today and tomorrow.

Flexibility

- Customisable platform to suit your bespoke needs.

- Handles any carton size, regardless of quality and humidity.

Reliability & Productivity

- Technical availability of over 98% (standard solution), even when running 24/7.

- Lightning-fast format changes with low adjustment time and downtime.

All you need, whenever you need it

Sticks, sachets and pouches

- Flex count infeed system for sticks, sachets and pouches

- Handles a wide variety of counts & speeds up to 900ppm

- Supports random formation of products or on edge to our other systems

Bottles and jars

- Supports single bottle per carton or more complicated multi-size combinations

- Handles simple feedscrews to multiple star wheel combinations

- Designed to minimize label & bottle surface contact to eliminate product surface marking

Facial tissue

- Accepts tissue clips directly from your upstream log saw and orient for the standard (flat) tissue cartons or cube (boutique) tissue cartons

- Maintains control of the clips from the discharge of the log saw until loaded into the carton

Blister strips

- Integrates directly to the upstream equipment or interface to your blister strip storage or sterilization system

- Blister strips can be nested and/or stacked or fed directly to the cartoner as a single strip

Bags

- Bags can be collated in a wide variety of formations prior to our cartoning systems

- Adaptable to handle speeds up to 100ppm

Frozen food

- Handles products gently so that toppings stay intact when stacked together at higher speeds, including pizzas

- Product collation in a wide variety of formations prior to carton loading

Flow wrap

- Fast and flexible star wheel or ‘bomb-bay’ feeding system

- Collates flow wraps in stacked or on edge formations

- Highly flexible and reliable linear servopack collation system

Trays

- Accommodates single tray supply, randomly spaced or multiple tray infeeds

- Trays can be reoriented for carton loading if required

- Supports one tray per carton, multiple trays per carton or a combination of both

Consumer goods

- We know specialised consumer goods need tailored solutions. So, through our years of expertise we have designed and built a wide range of infeed systems to match. From batteries to household products, jugs, and more, we’re on hand to support your needs

- Accommodates single tray supply, randomly spaced or multiple tray infeeds

- Trays can be reoriented for carton loading if required

- Supports one tray per carton, multiple trays per carton or a combination of both

Stay ahead of the competition

Be first-to-market with a scalable, robust solution.

Contact Us >