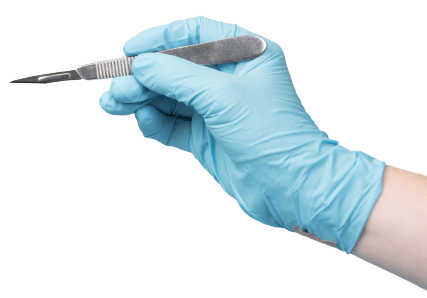

With a rising number of surgical procedures accelerating the global demand for surgical scalpels, you have no choice but to max your manufacturing line. But this persistent pressure can overwhelm standard assembly platforms, halting production and blunting your reputation.

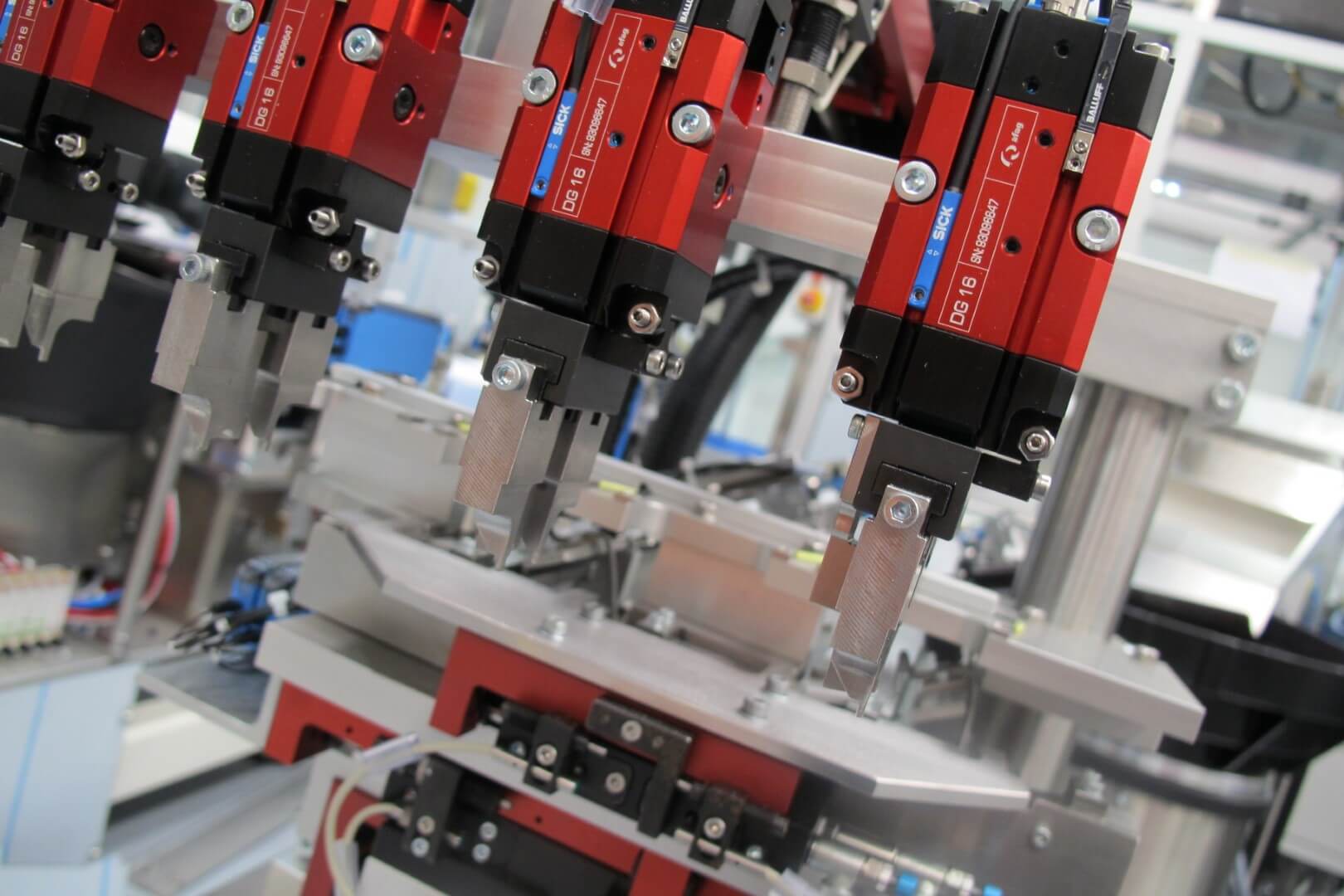

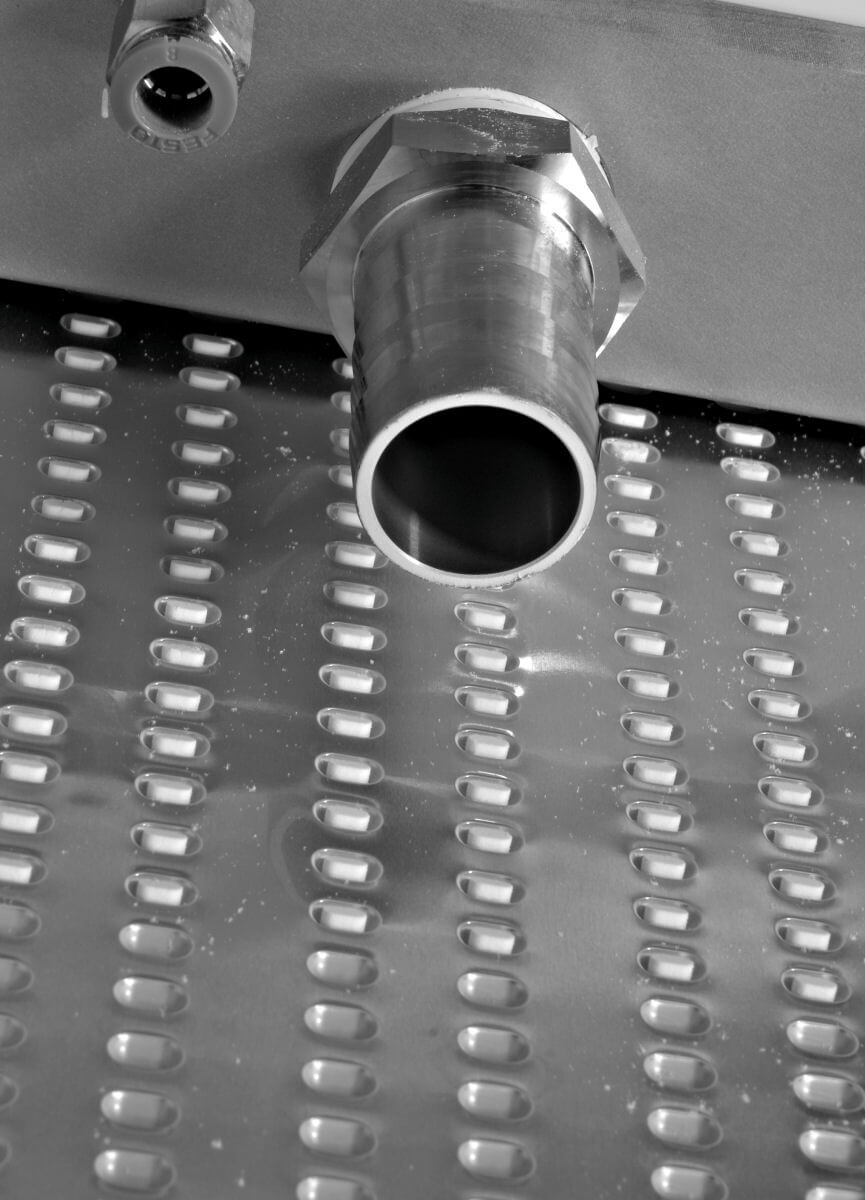

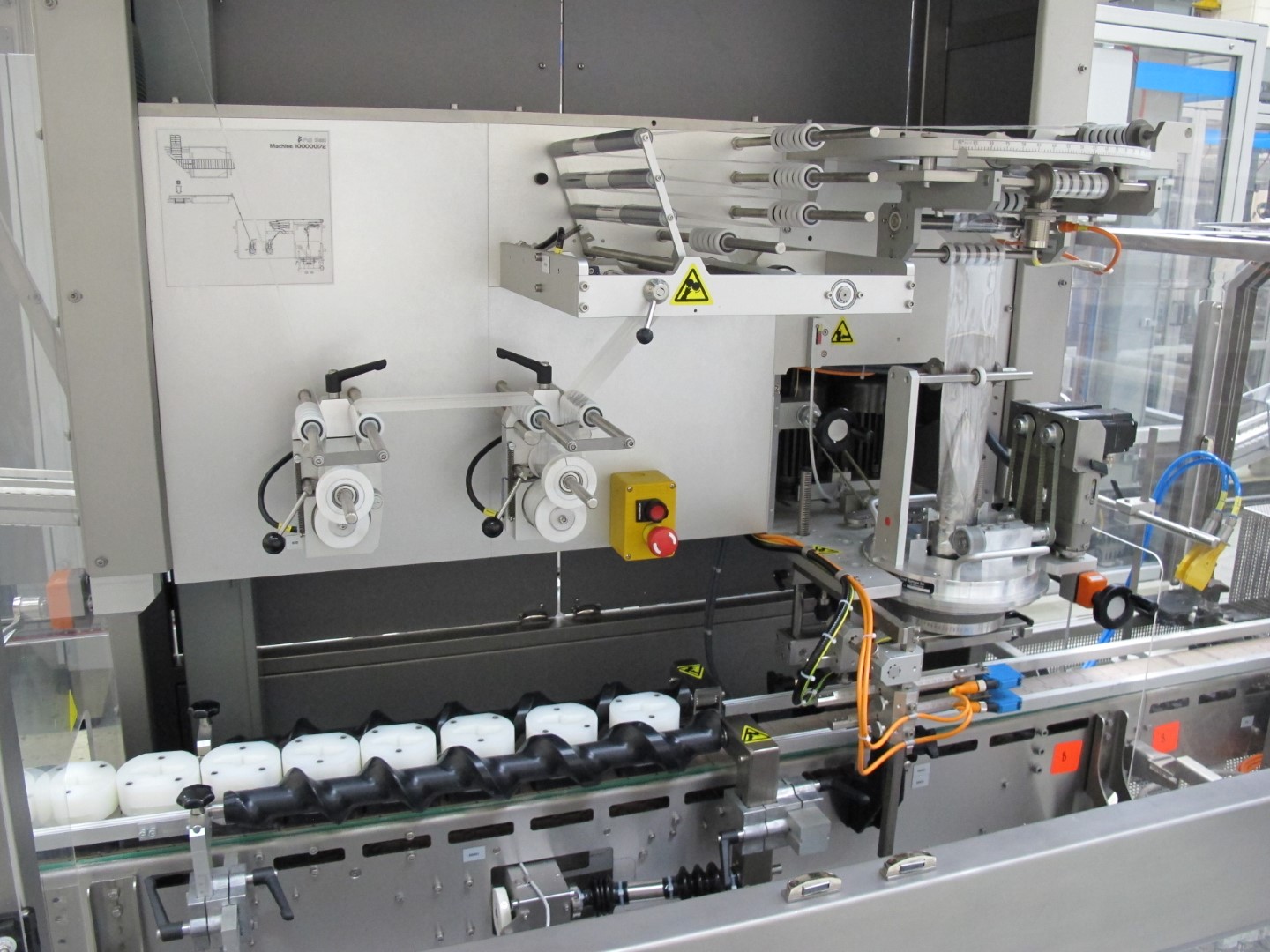

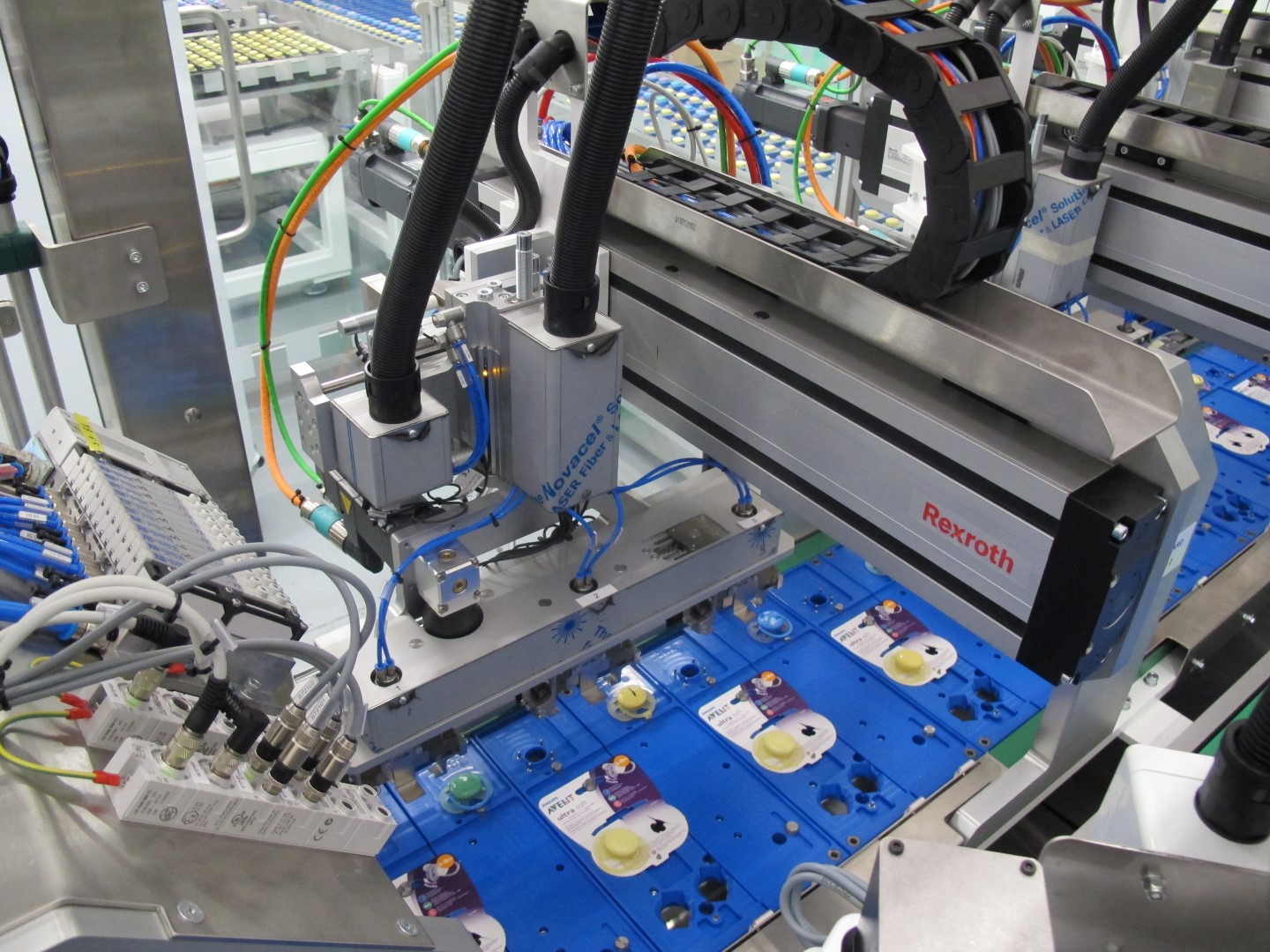

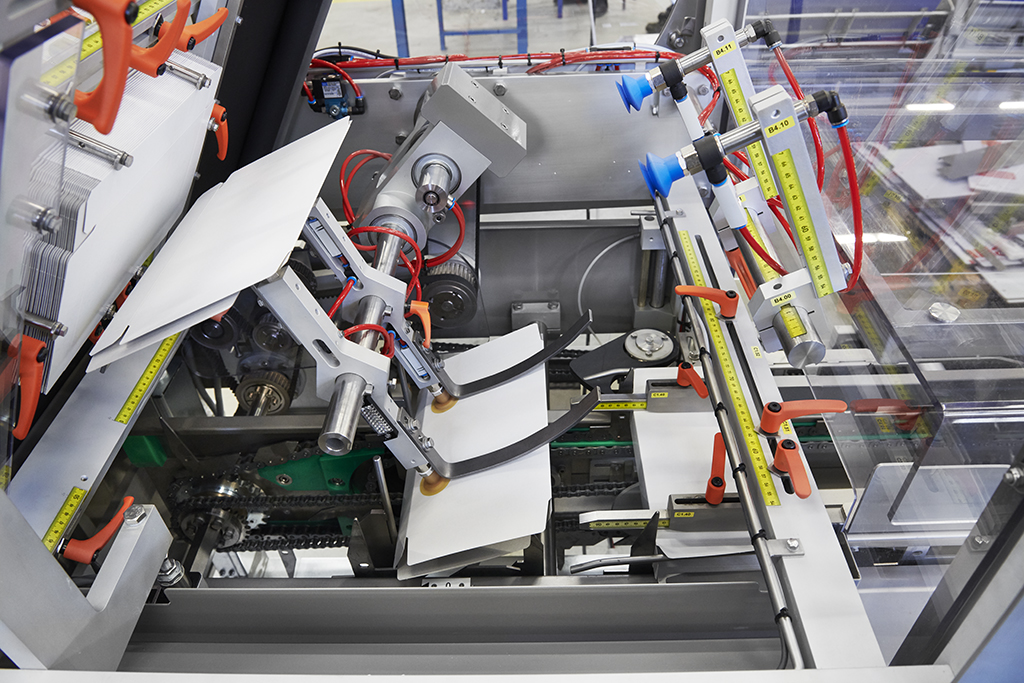

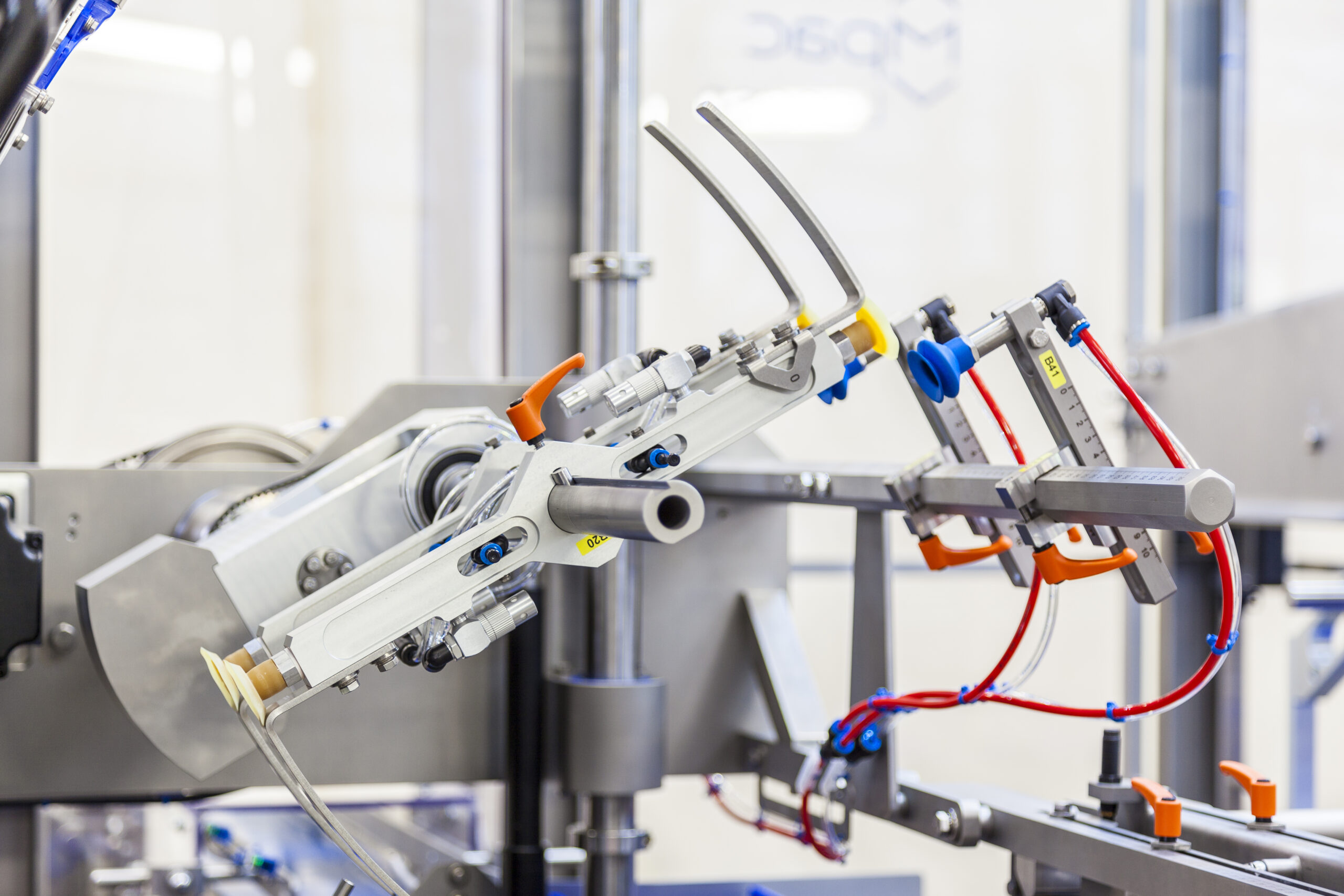

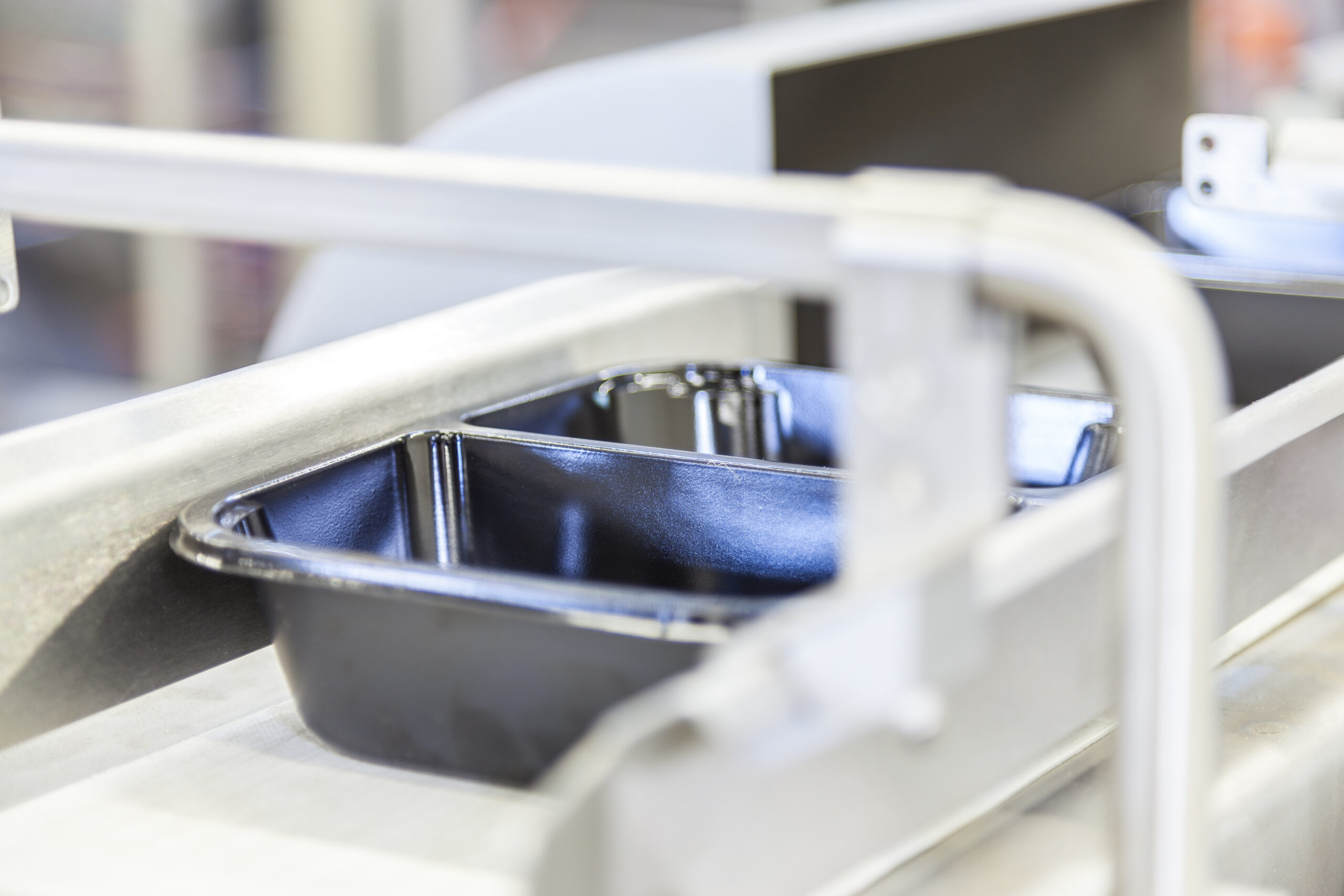

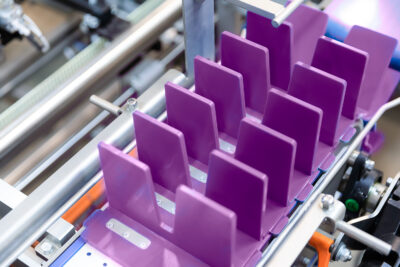

Luckily, our flexible platforms rapidly adapt to keep your lines flowing, with the ability to handle a wide range of blade shapes and sizes. And naturally, easy to operate, incredibly hygienic, and conform to the highest standards of quality inspection.

Scalpel blade capabilities:

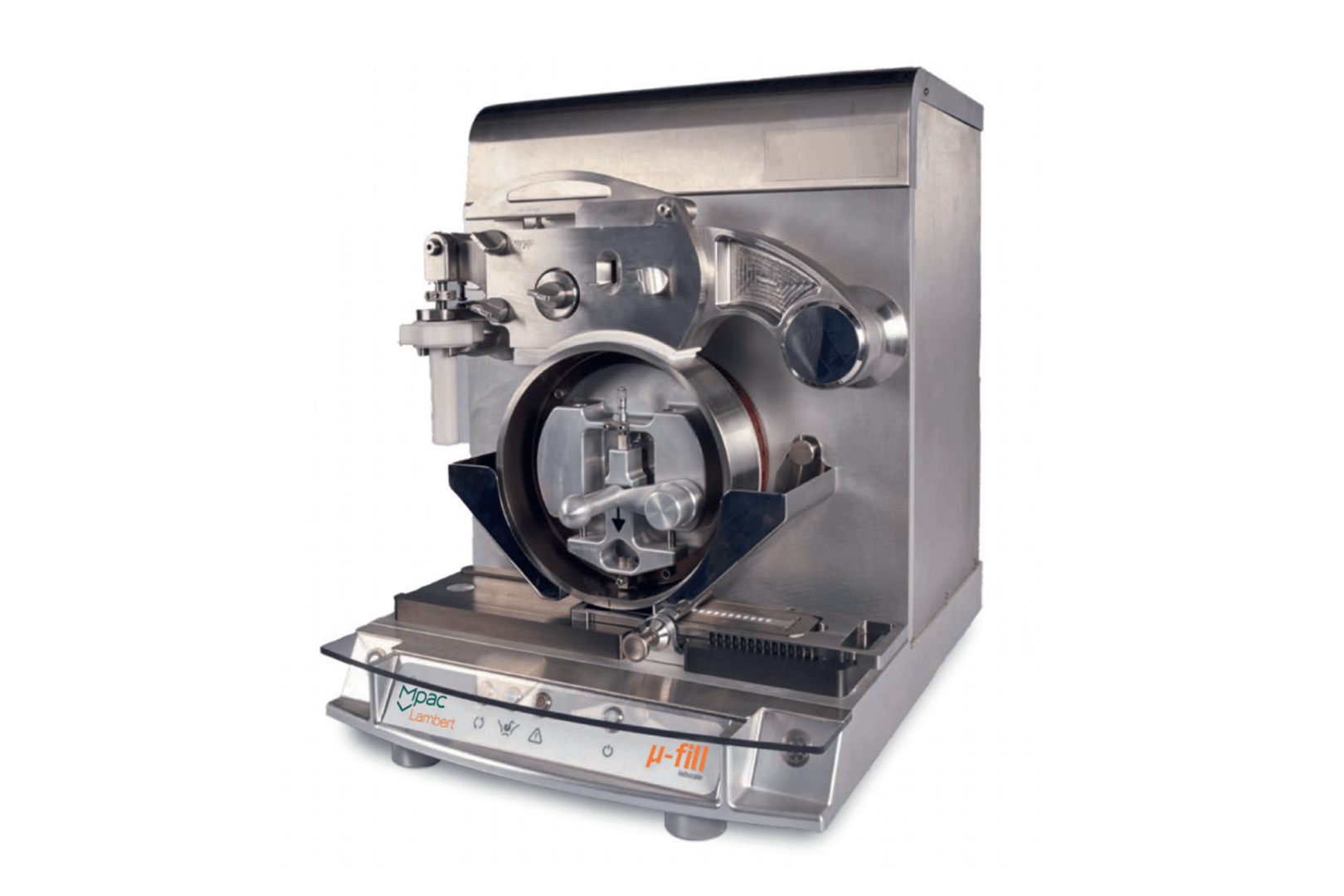

Our next-generation platforms handle a variety of surgical blade shapes and sizes, and are trusted by many of the world’s leading surgeons and veterinary surgeries.

Our Approach

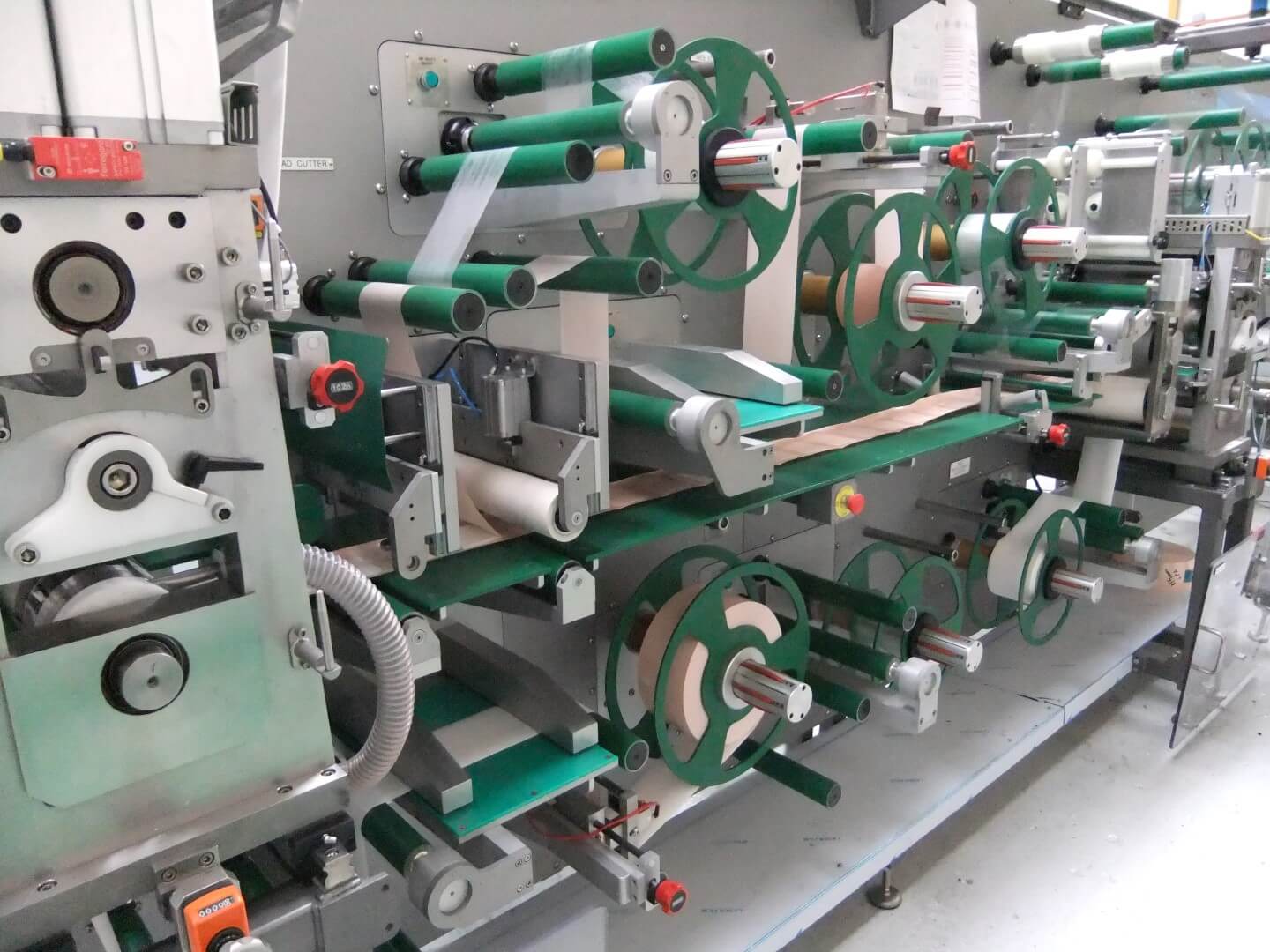

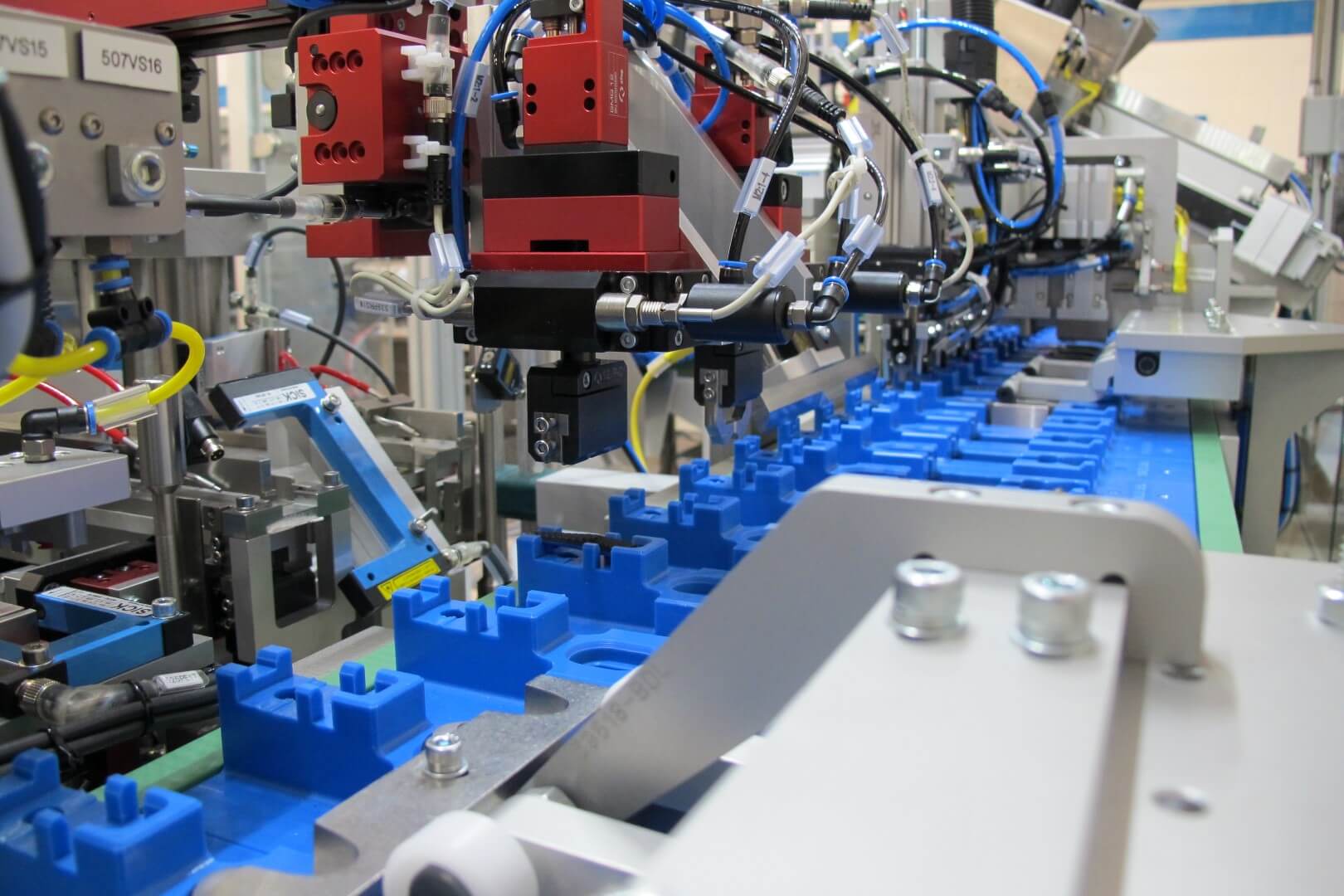

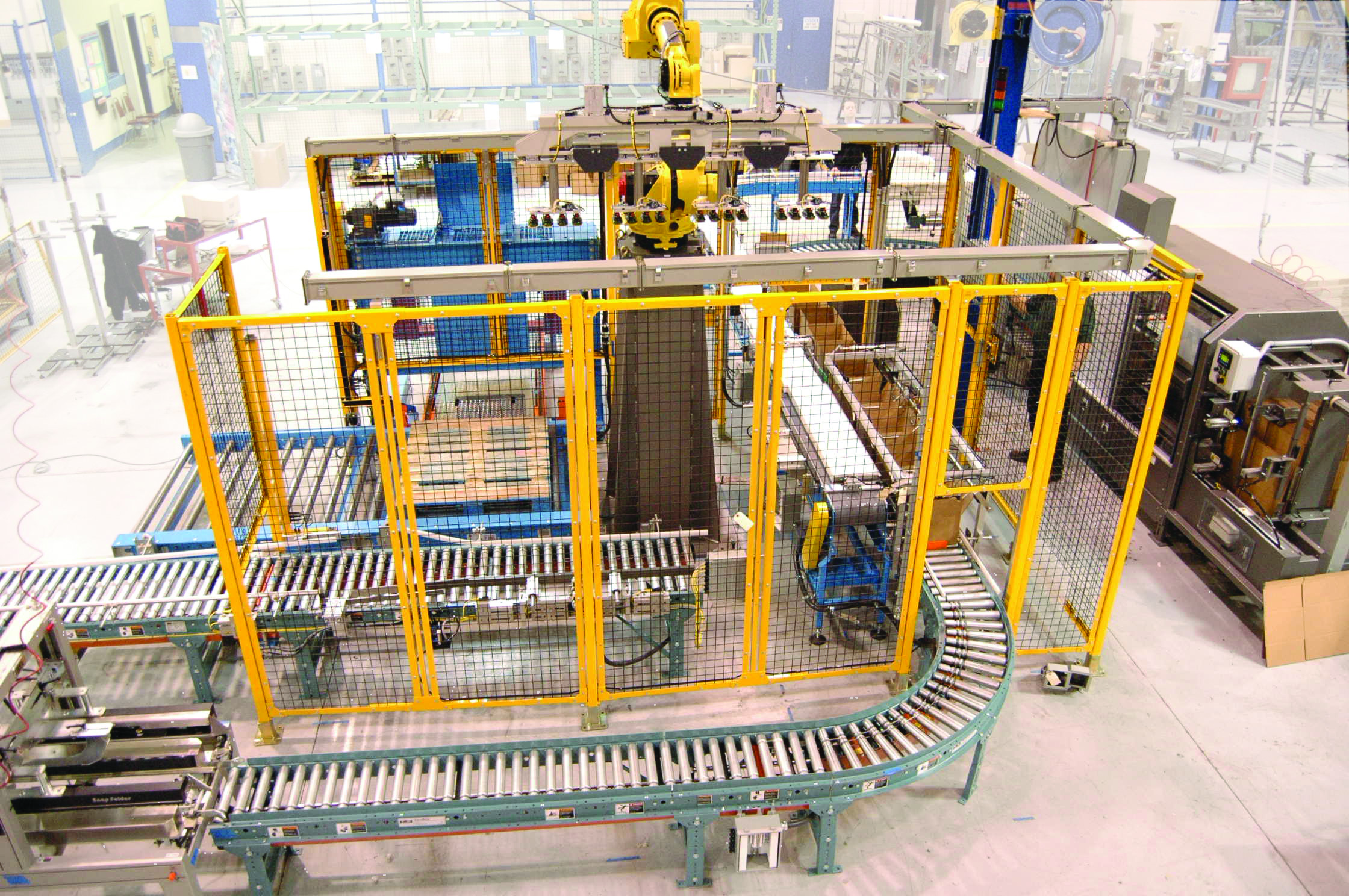

Forget what you know about the limits of scalpel blade assembly. Whether you require standard or tailored solution, our industry-leading machines are capable of exceeding your expectations.

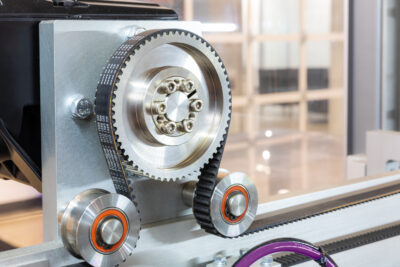

Mpac Group’s automation machine experts will take the time to listen to your bespoke needs and advise you on the best platform for your scalpel blade production line. We go above and beyond to ensure our machines are robust, stable and scalable to give you the most cost-effective packing solution on the market with the highest equipment efficiency.

Contact our world-leading engineers

Our world-class engineers support every stage of your evolution. To discuss your requirements with a member of our friendly team, get in touch by filling out the enquiry form opposite.