As the global infant care market continues to grow, so does the pressure to keep up with dummy production demand. But maxing out your machines can overwhelm standard equipment, halting production and failing to pacify your consumer’s needs.

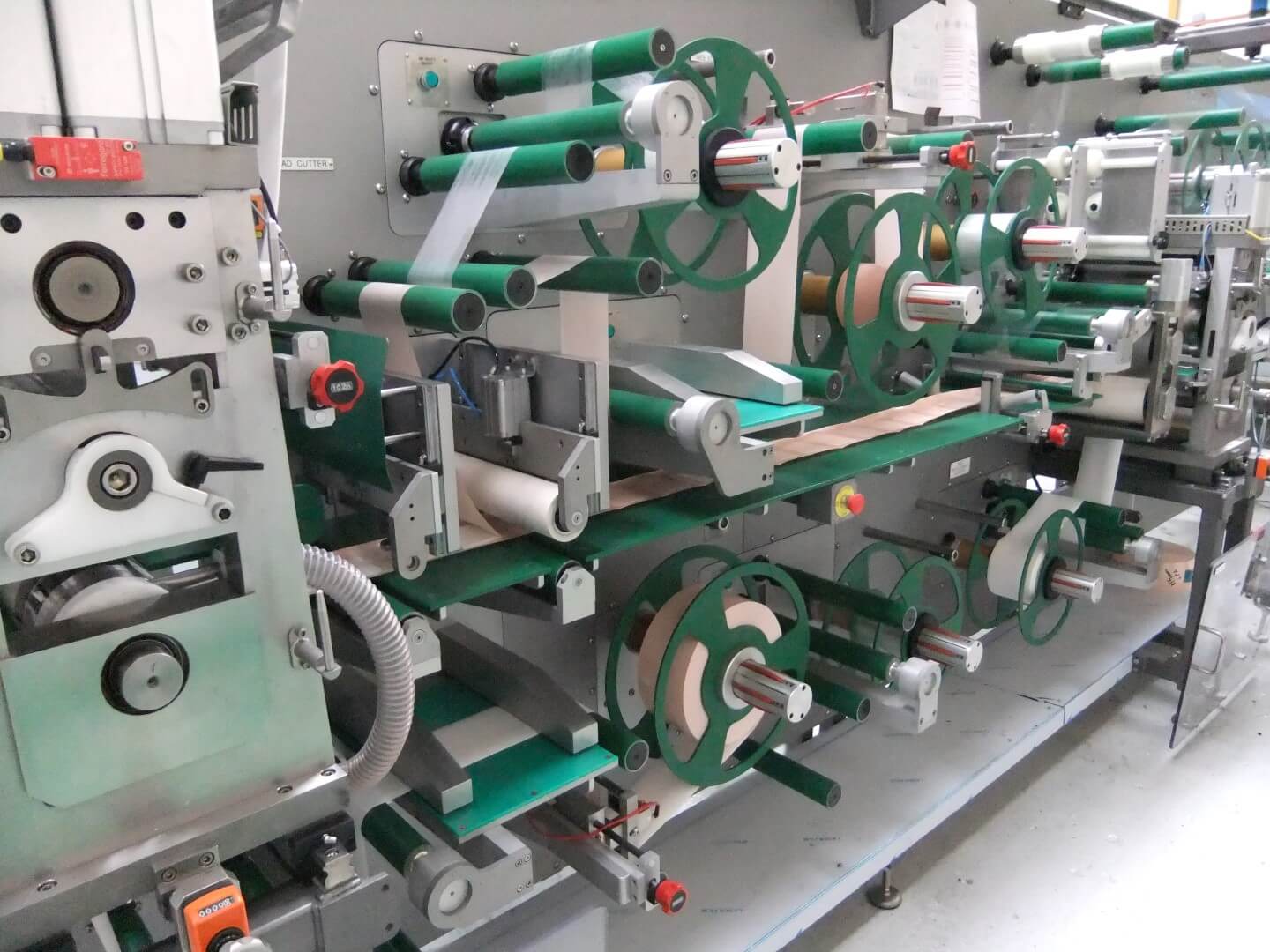

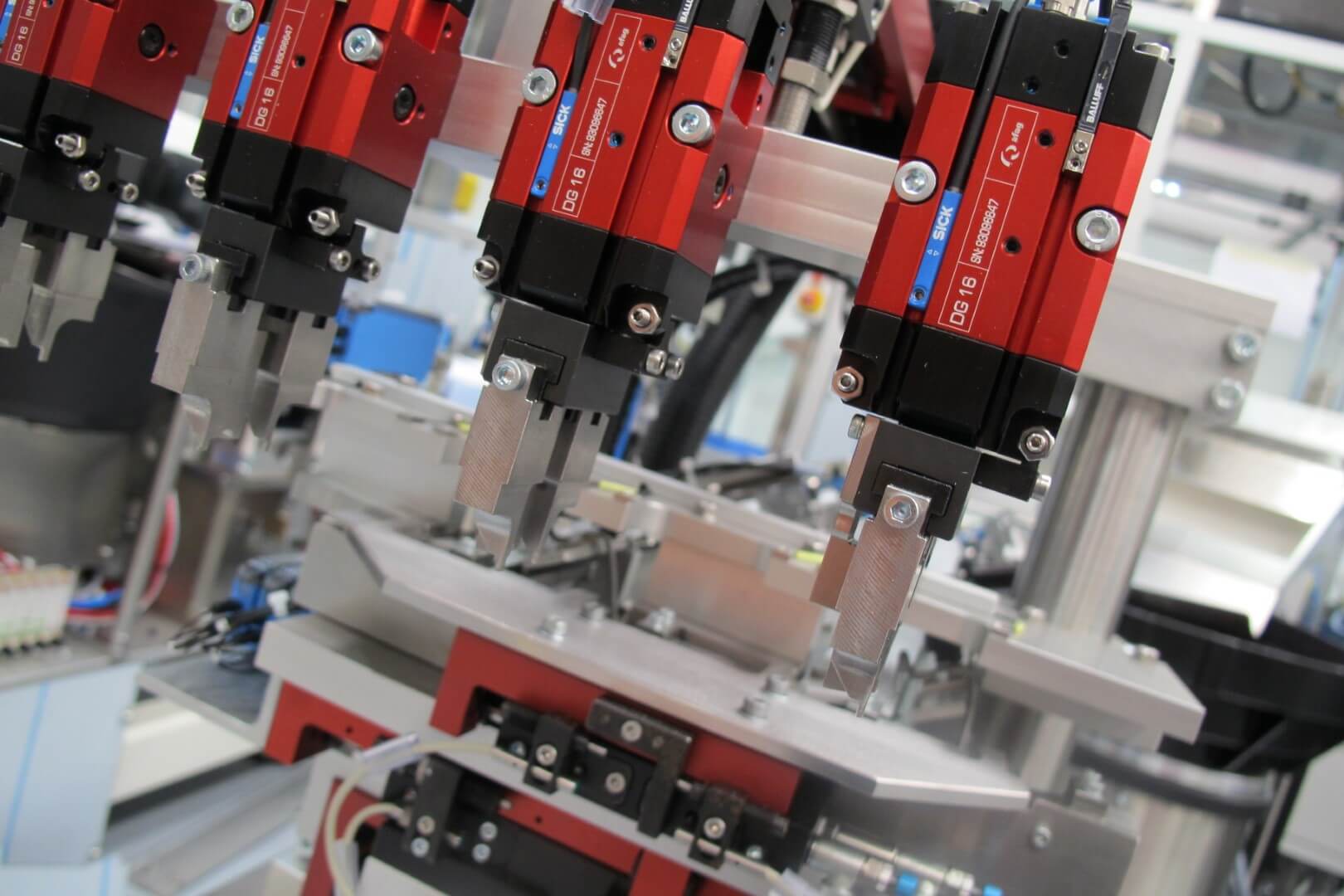

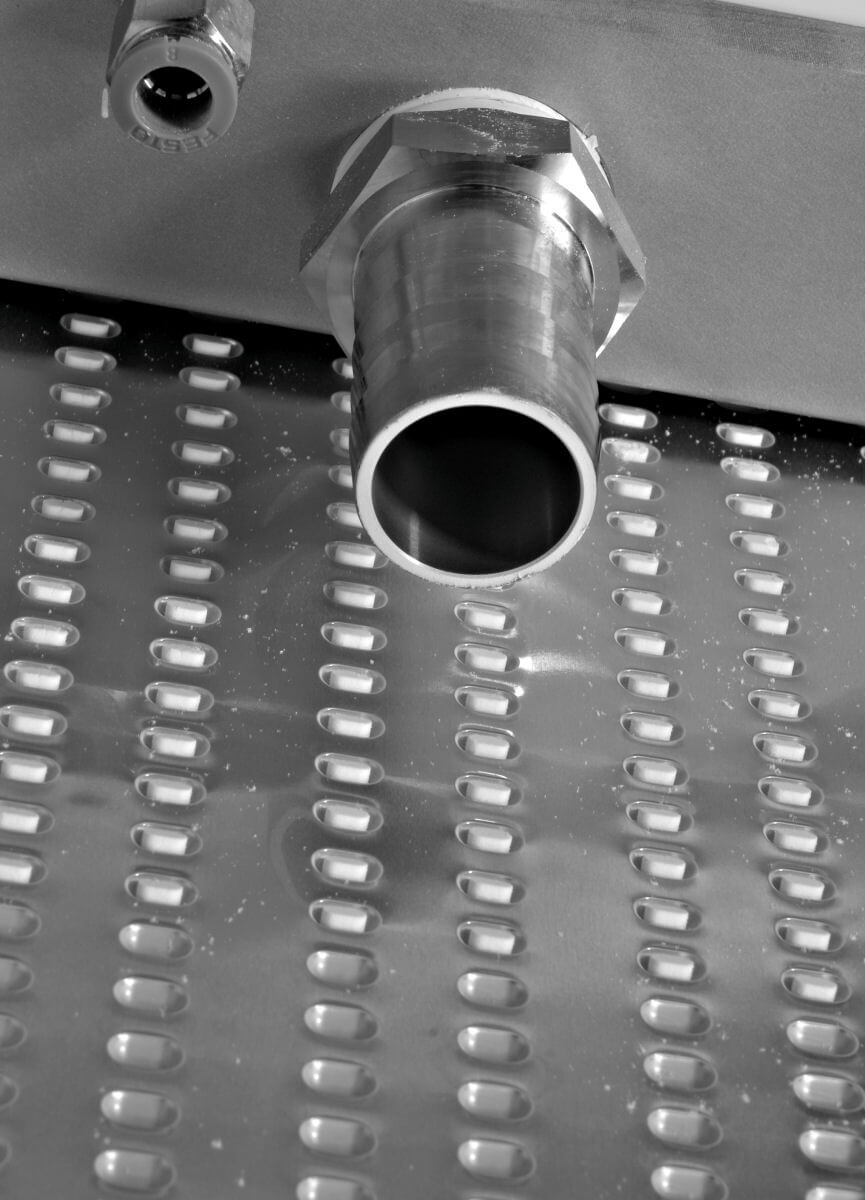

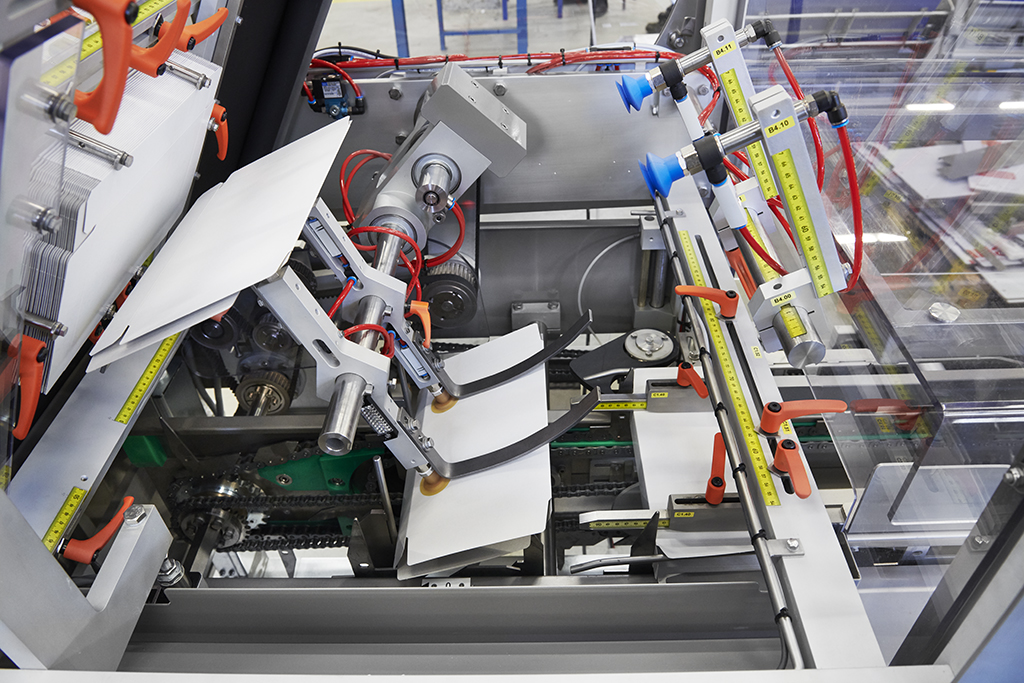

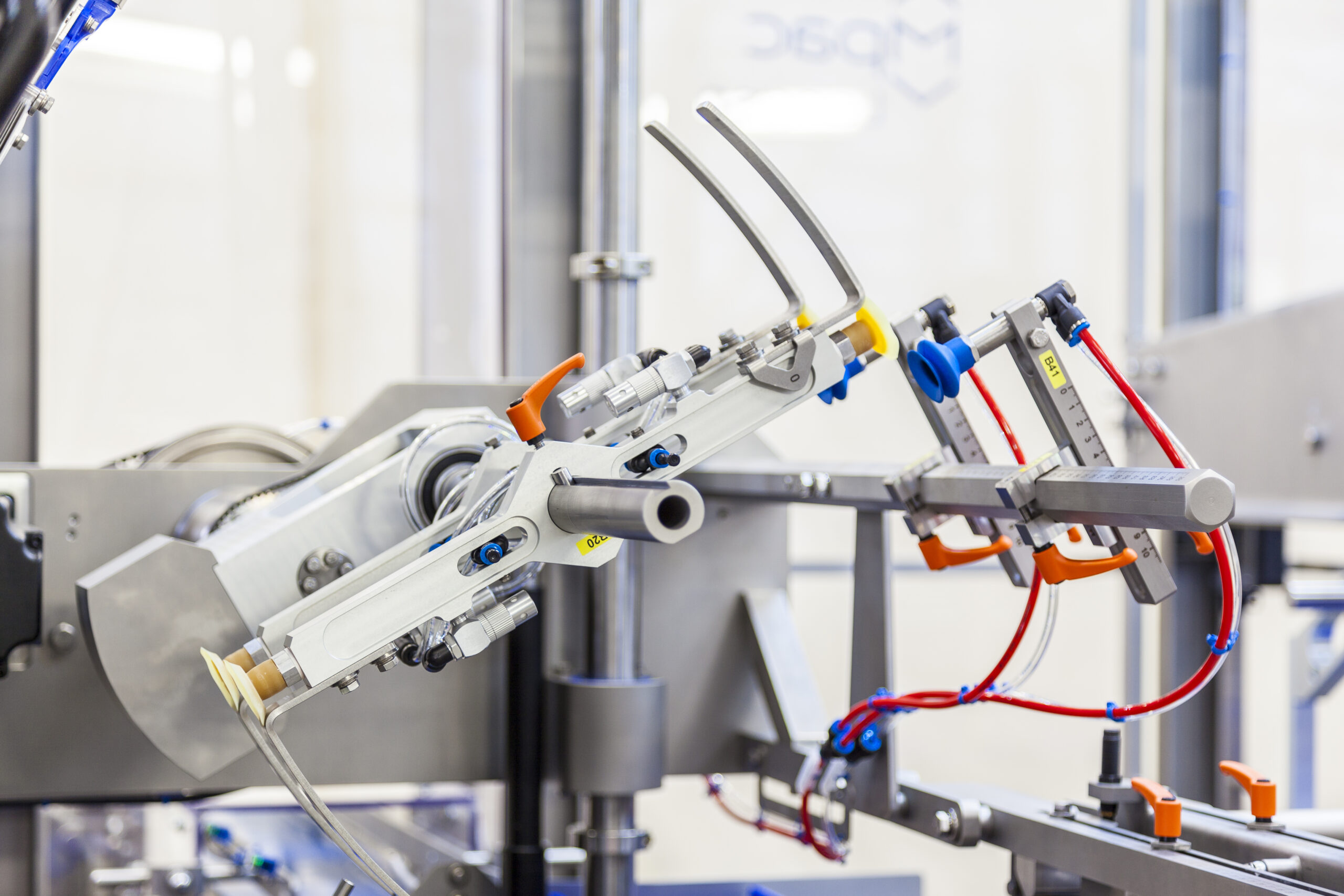

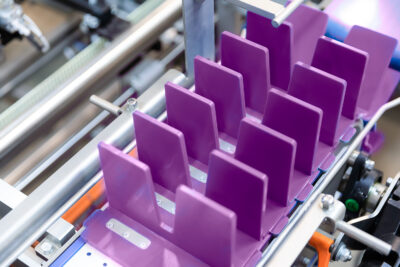

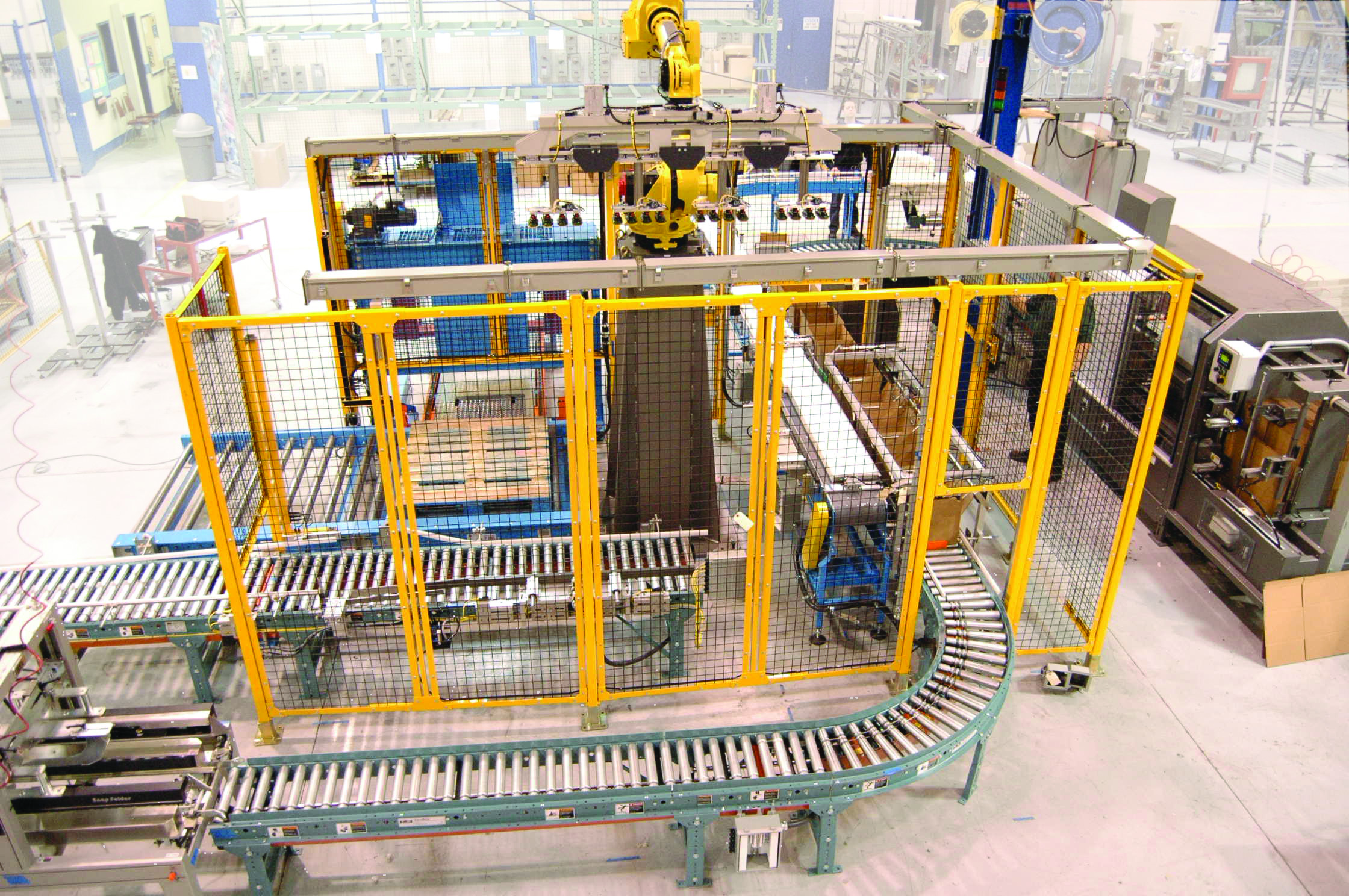

Luckily, our flexible platforms rapidly adapt to keep your lines flowing, with the ability to handle complex silicon parts quickly and efficiently. And naturally, they’re easy to operate, incredibly hygienic, and conform to the highest standards of quality inspection.

Our infant care cartoner capabilities include:

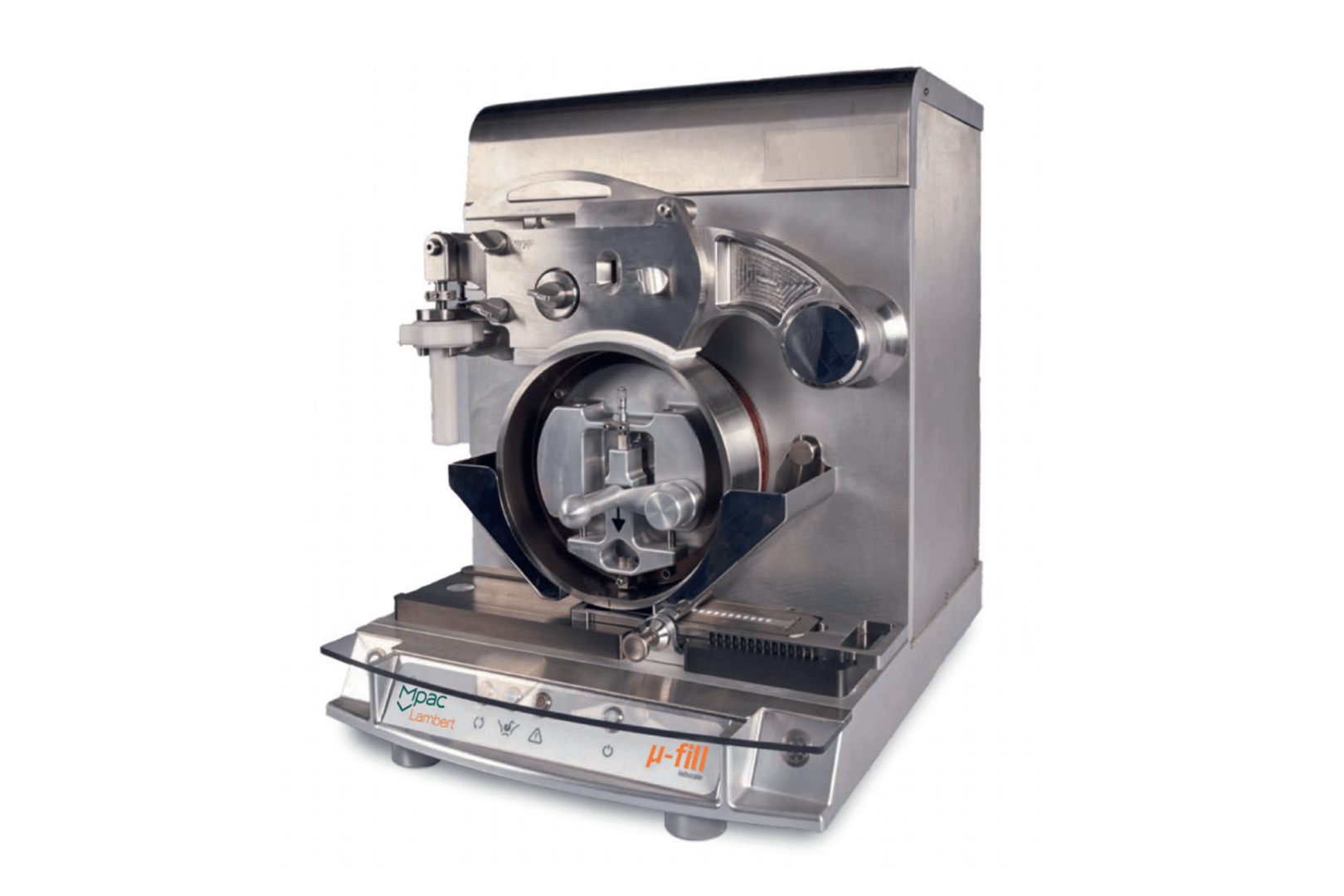

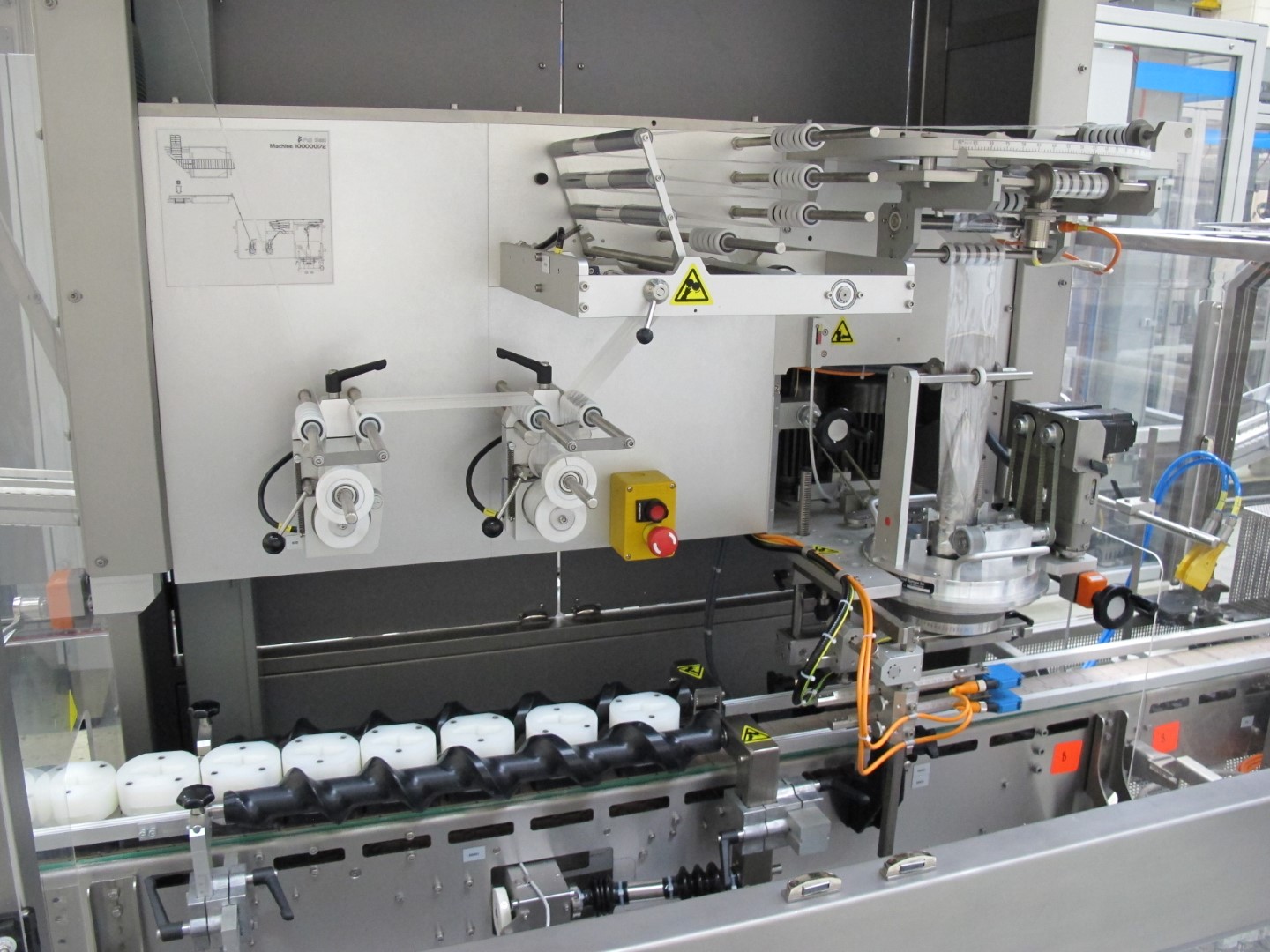

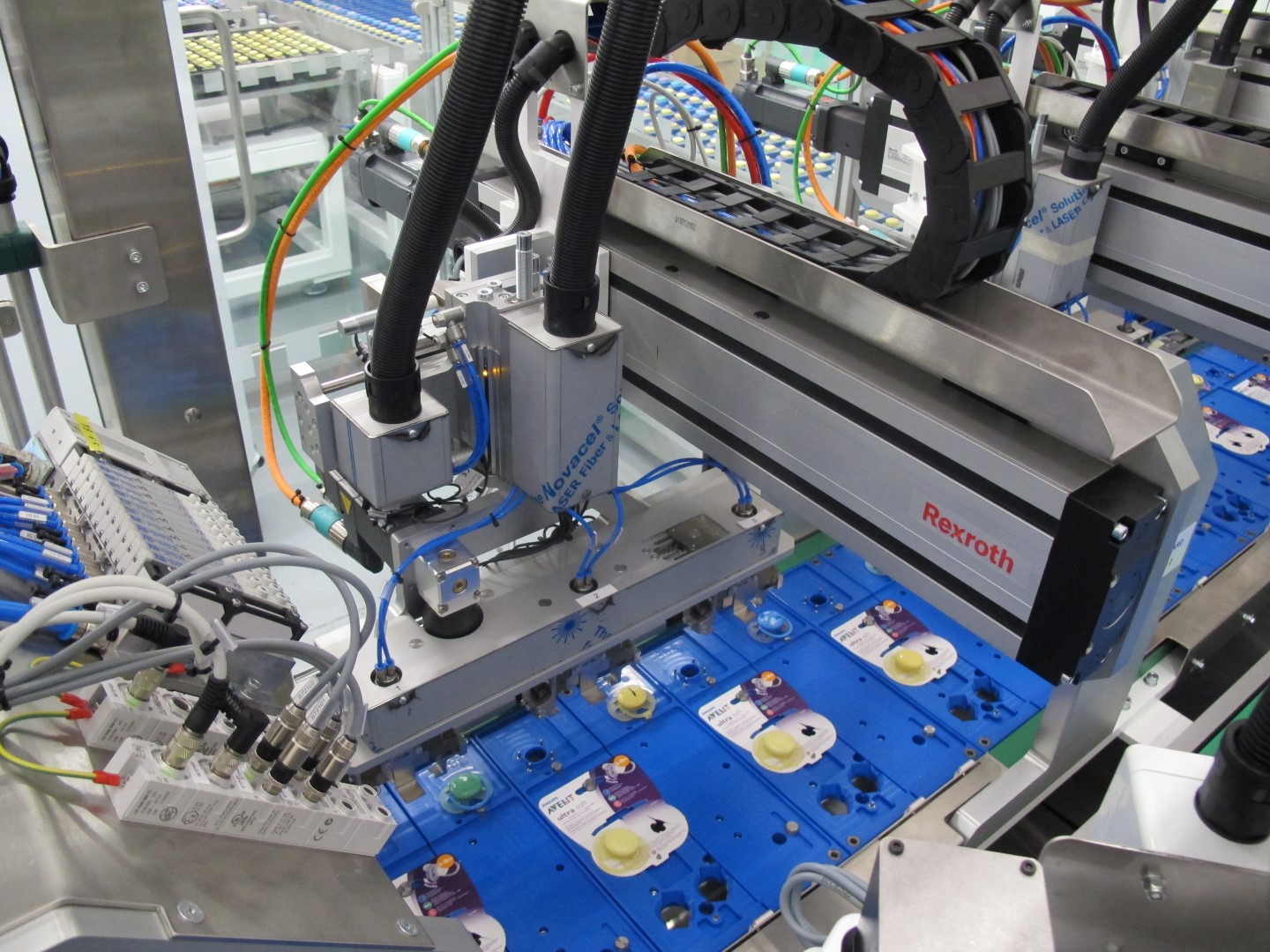

> Dummies (pacifiers): we assemble and primary pack dummies for leading health technology companies.

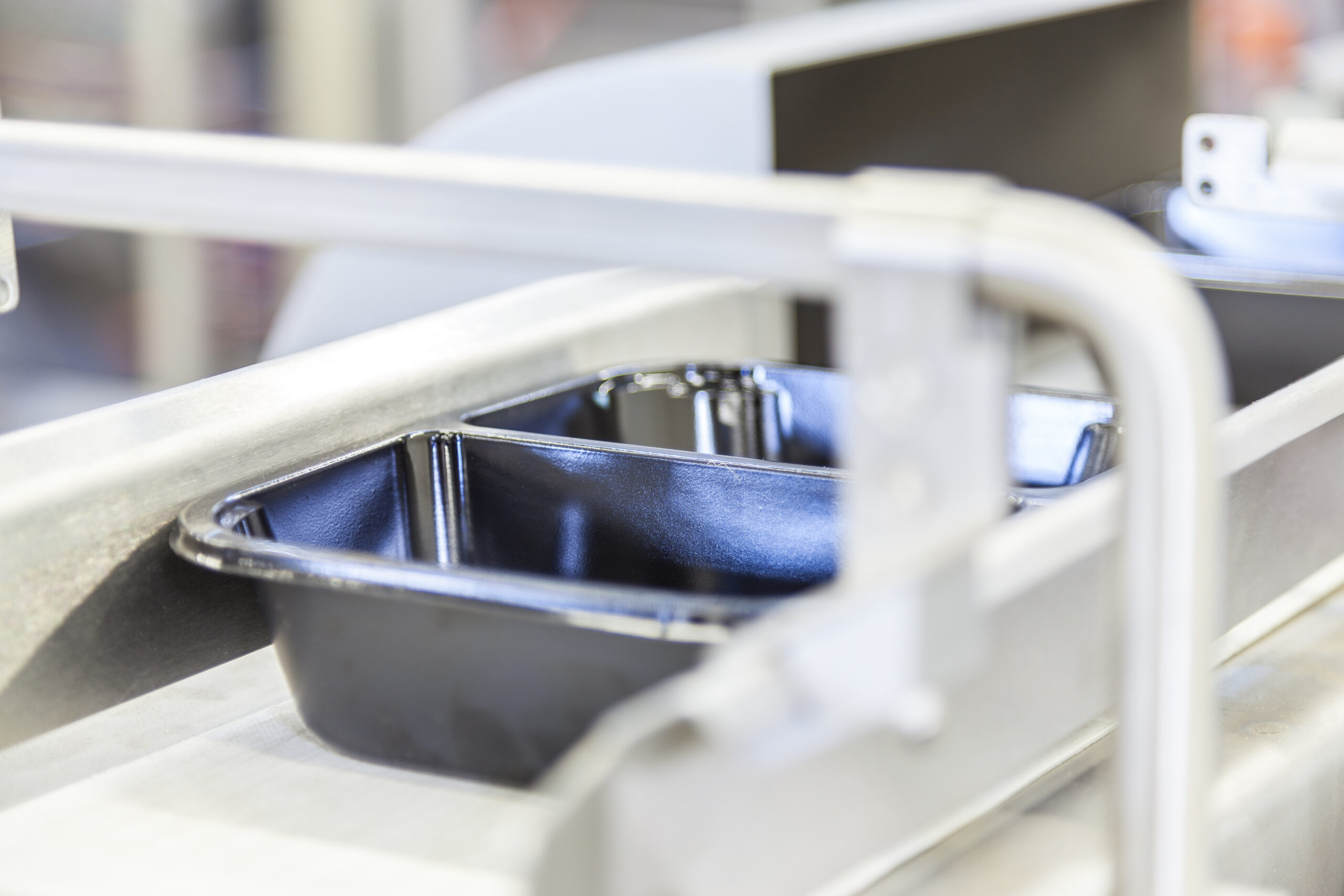

> Silicon bottle teats: fed into Mpac Group platforms before being capped and fitted with a screw-ring.

Our Approach

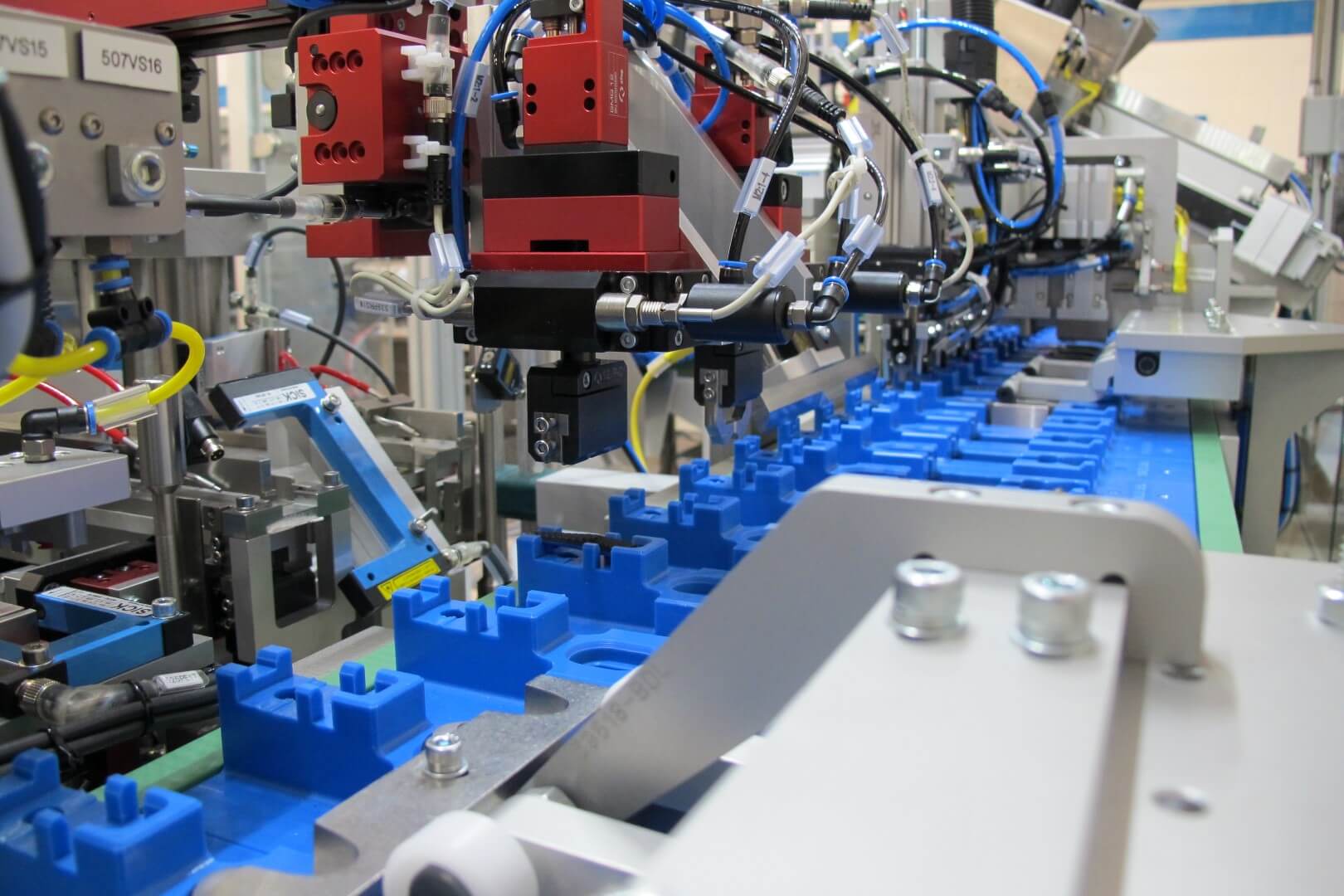

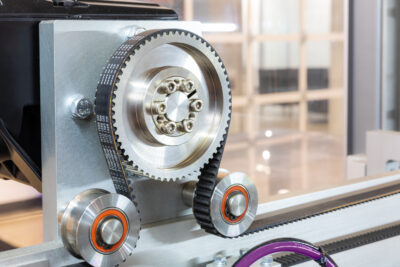

Forget what you know about the limits of infant care product assembly. Whether you require standard or tailored solution, our industry-leading machines are capable of exceeding your expectations.

Mpac Group’s automation machine experts will take the time to listen to your bespoke needs and advise you on the best platform for your pacifier production line. We go above and beyond to ensure our machines are robust, stable and scalable to give you the most cost-effective packing solution on the market with the highest equipment efficiency.

Contact our world-leading engineers

Our world-class engineers support every stage of your evolution. To discuss your requirements with a member of our friendly team, get in touch by filling out the enquiry form opposite.