Ostomy surgery saves thousands of lives each year. But growing demand for this type of surgery can overwhelm standard ostomy product cartoners. The result? Production pauses while products pile up.

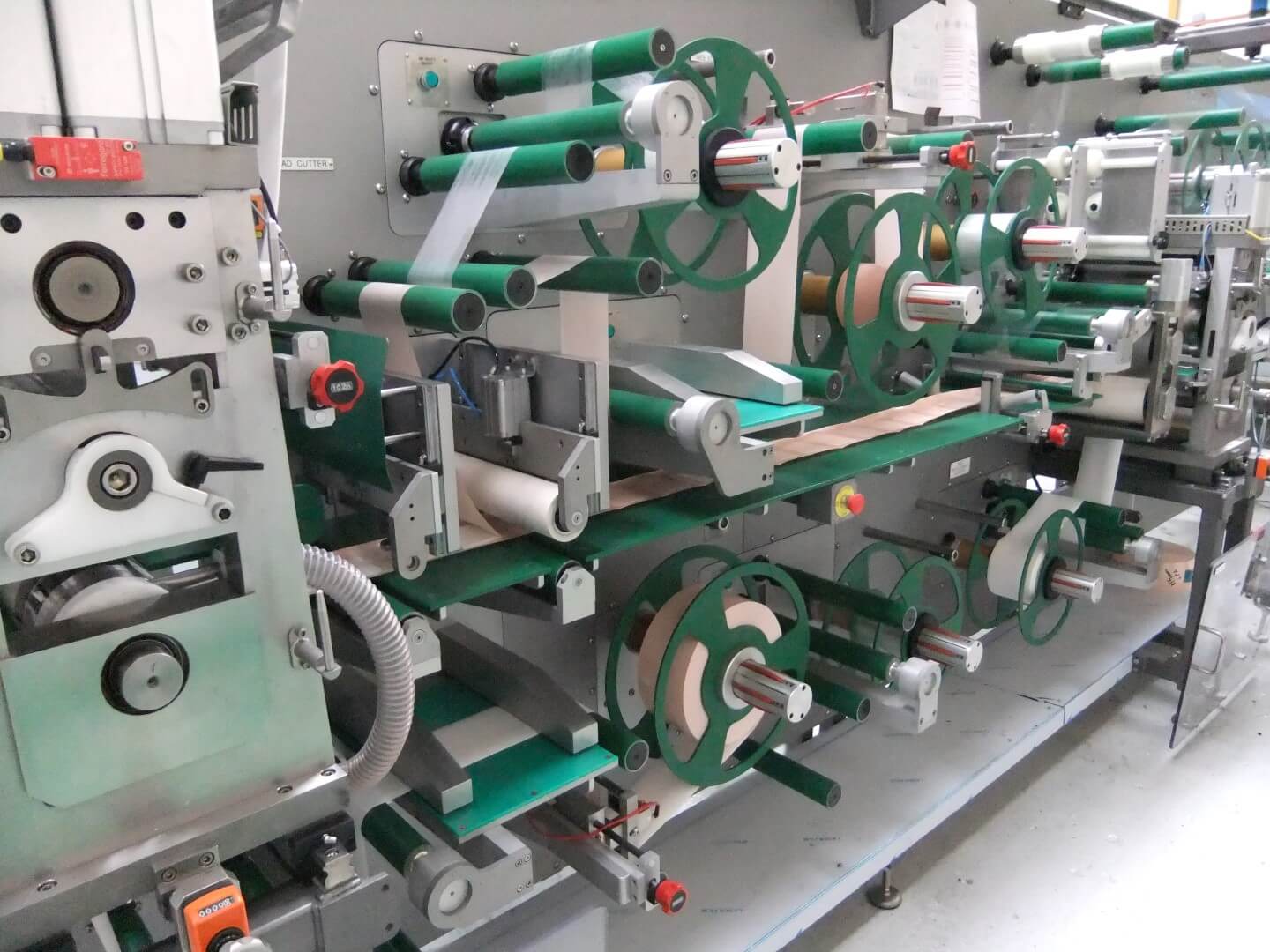

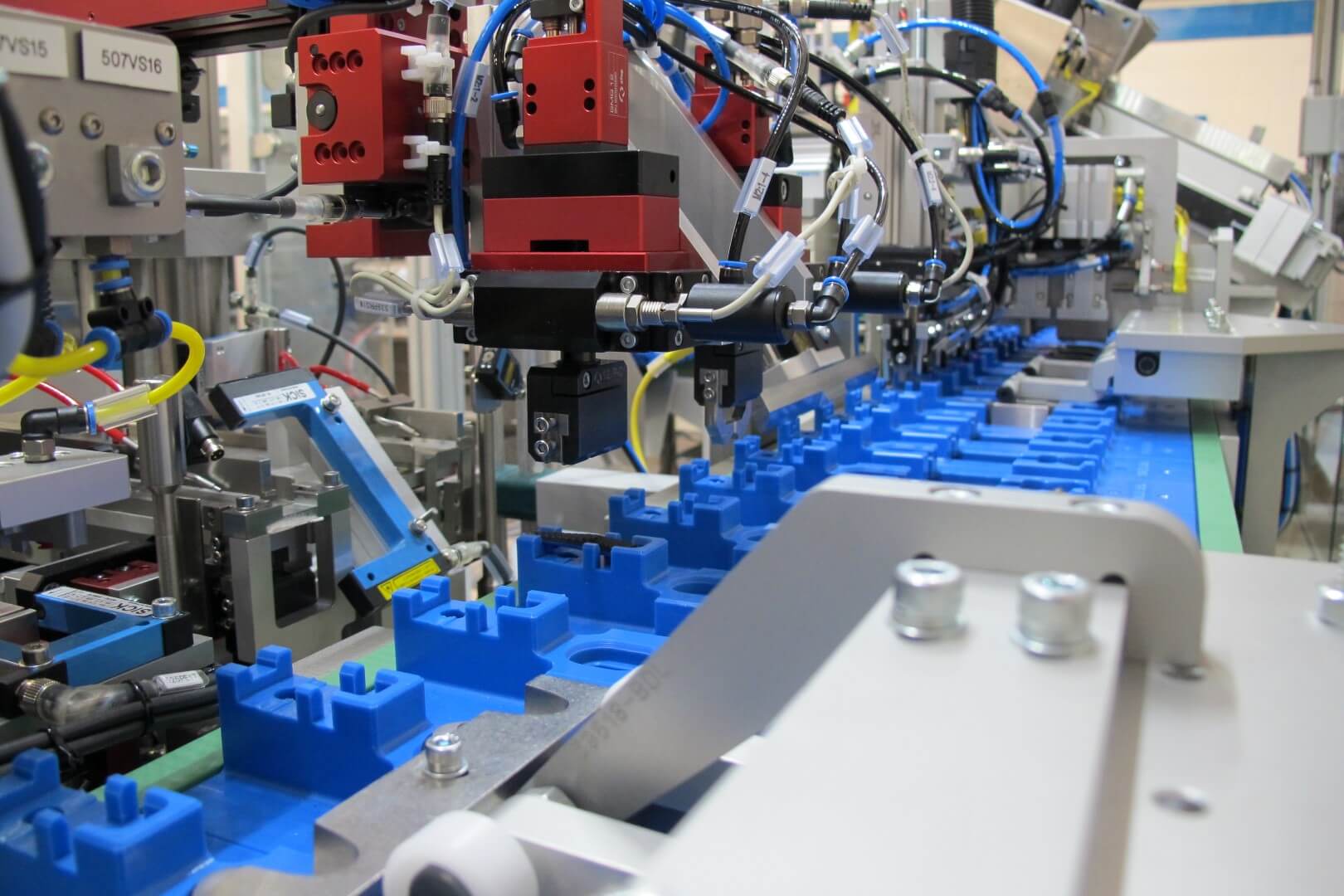

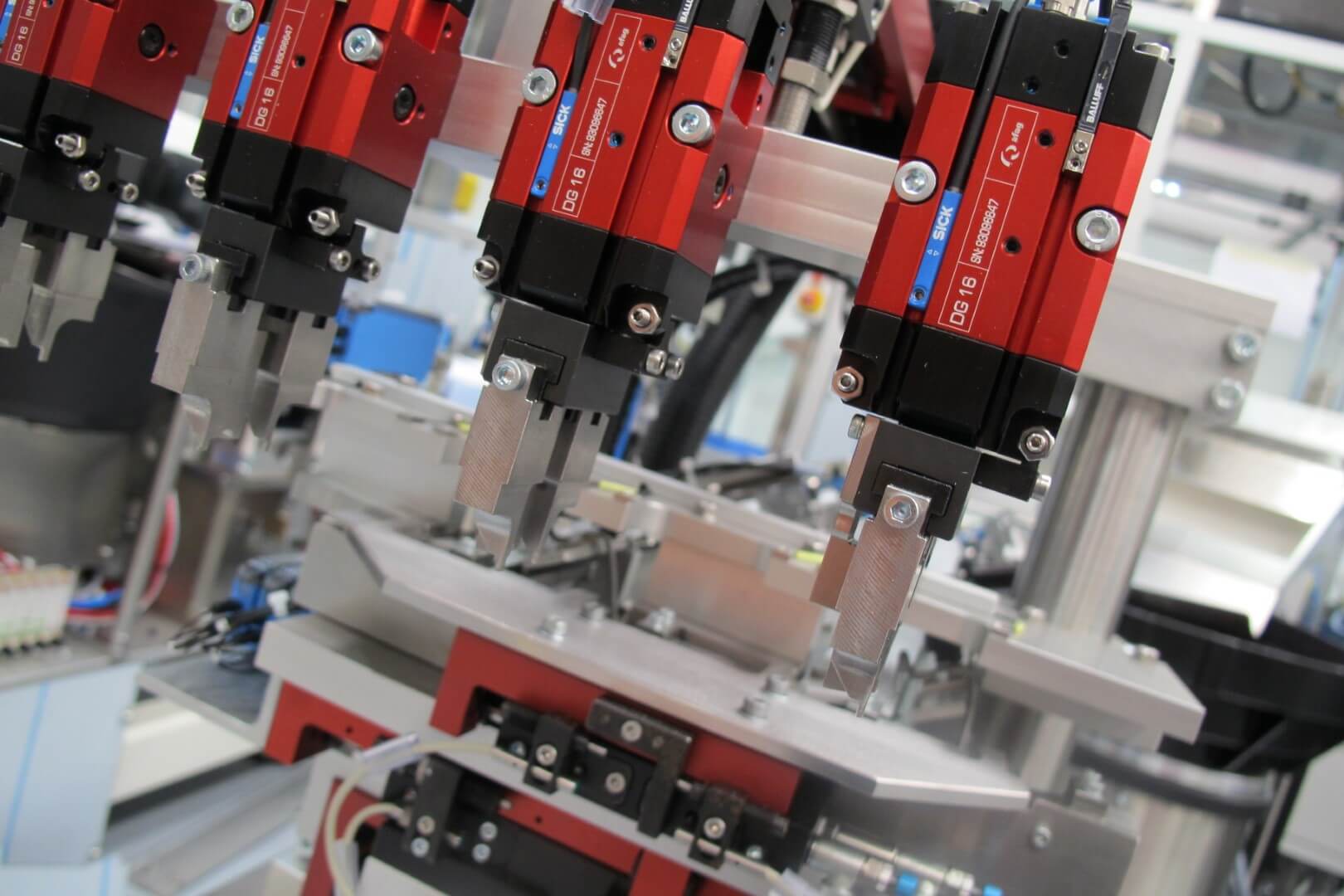

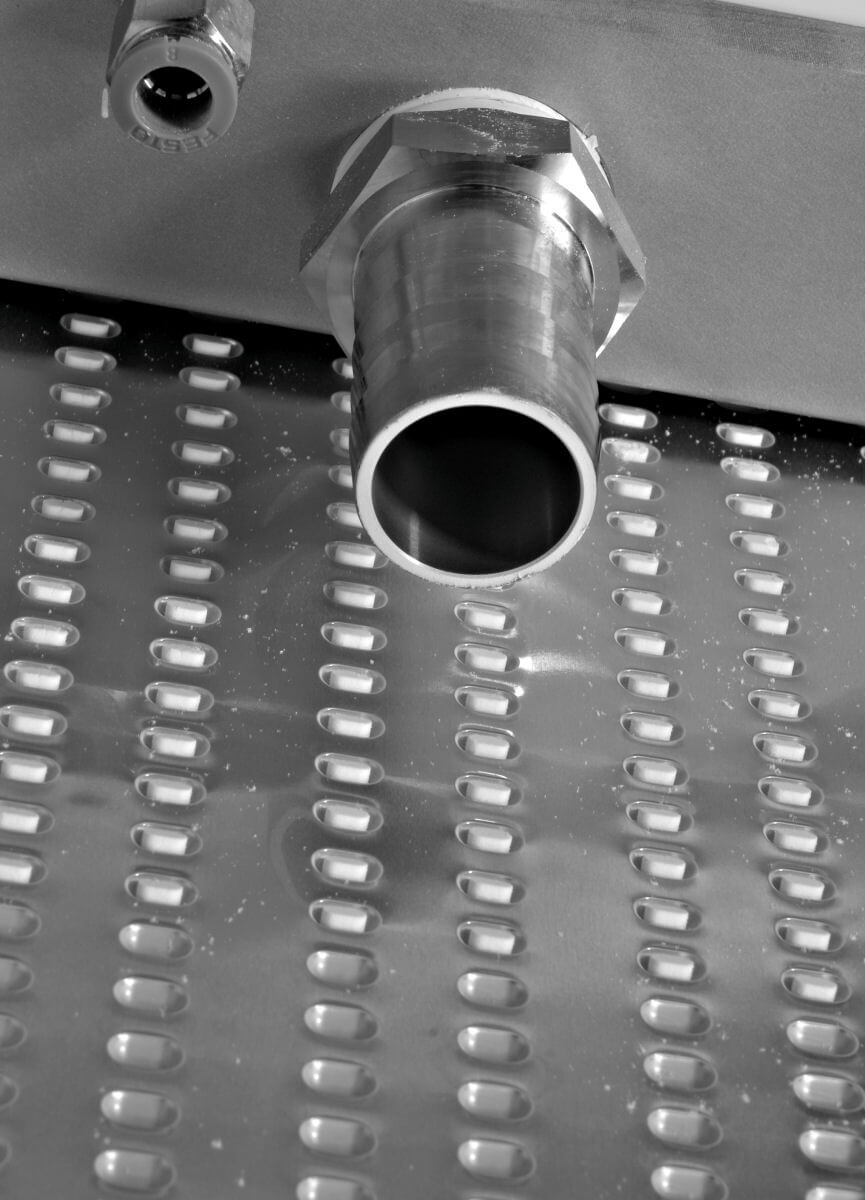

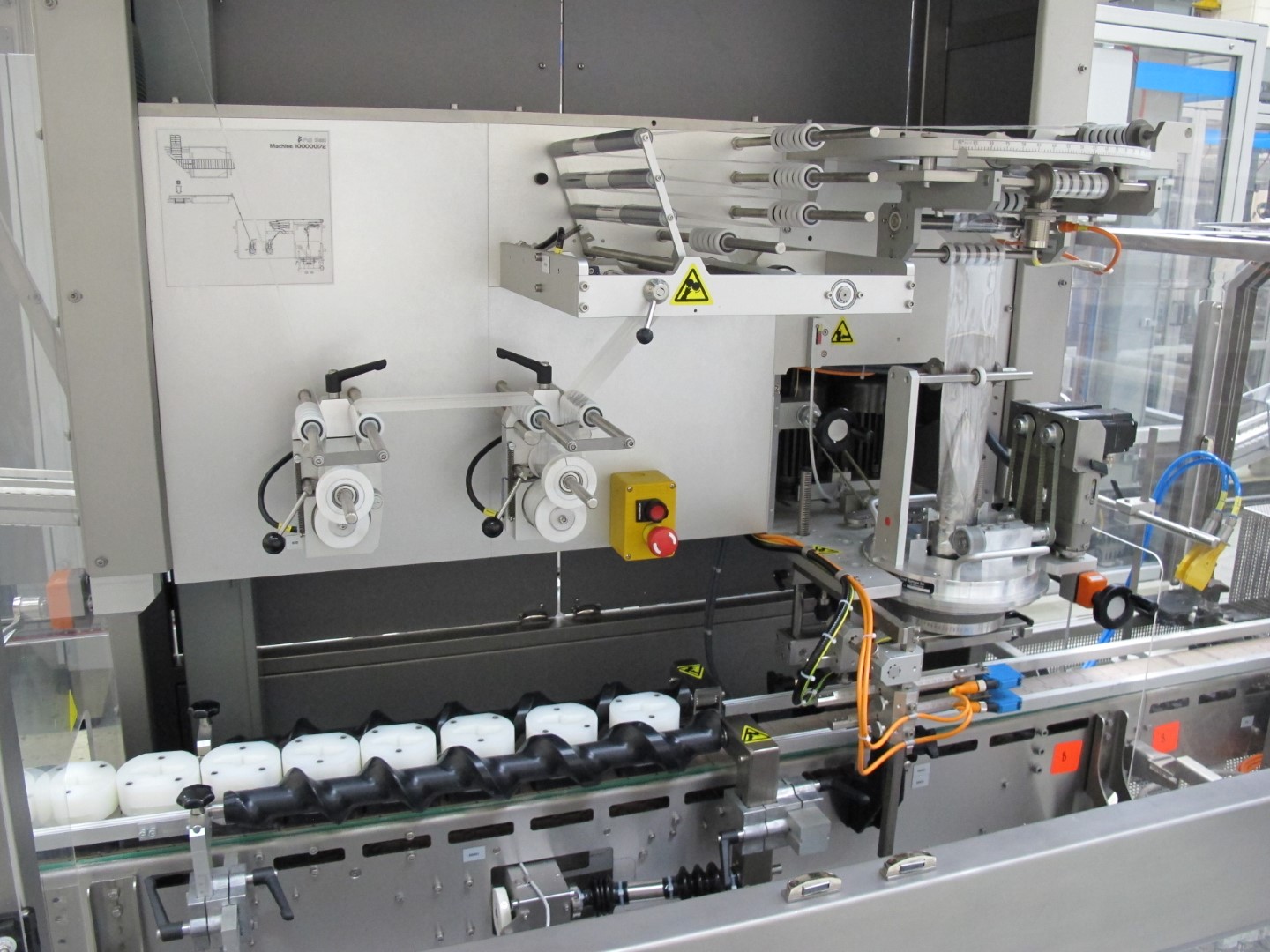

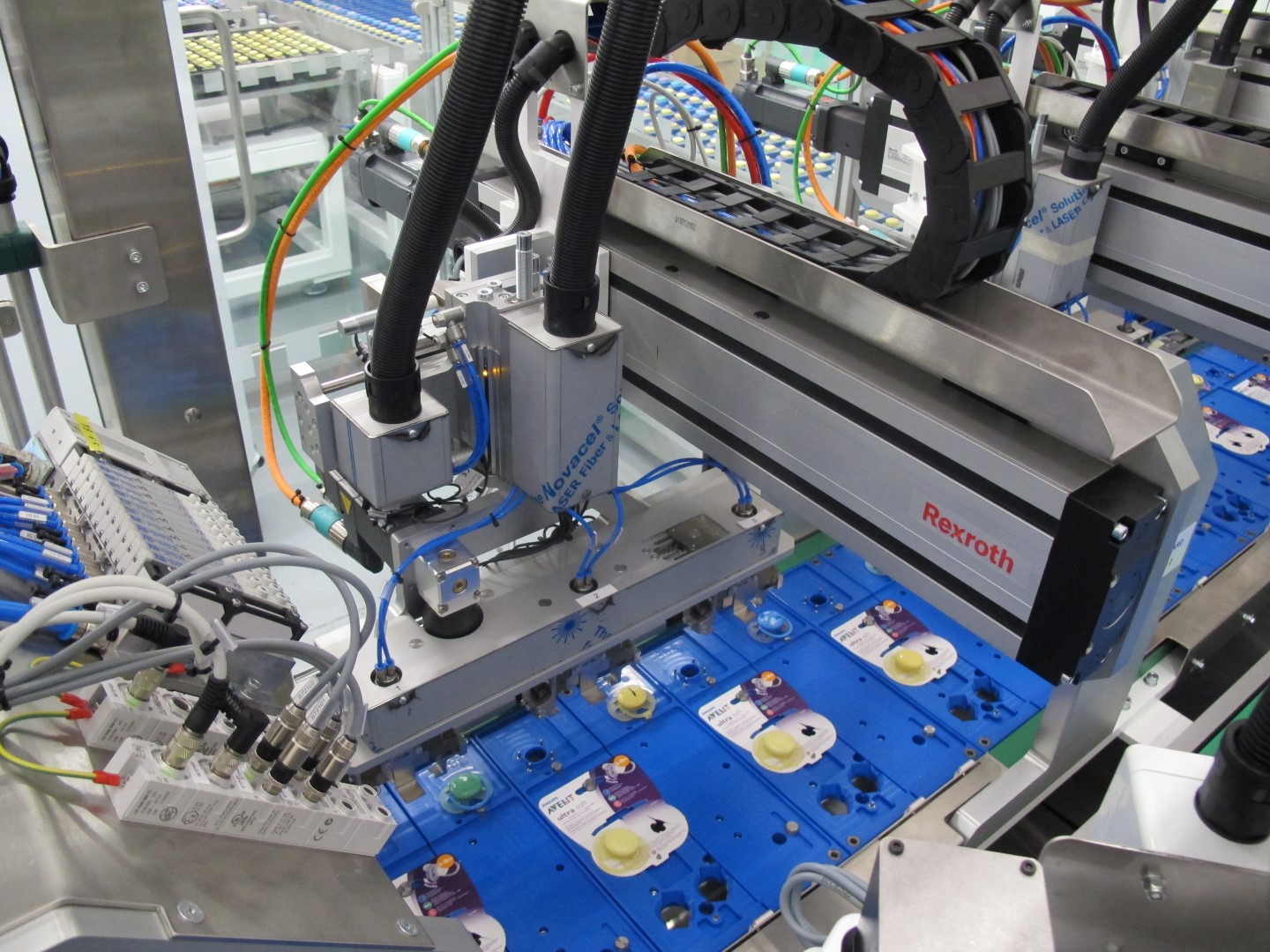

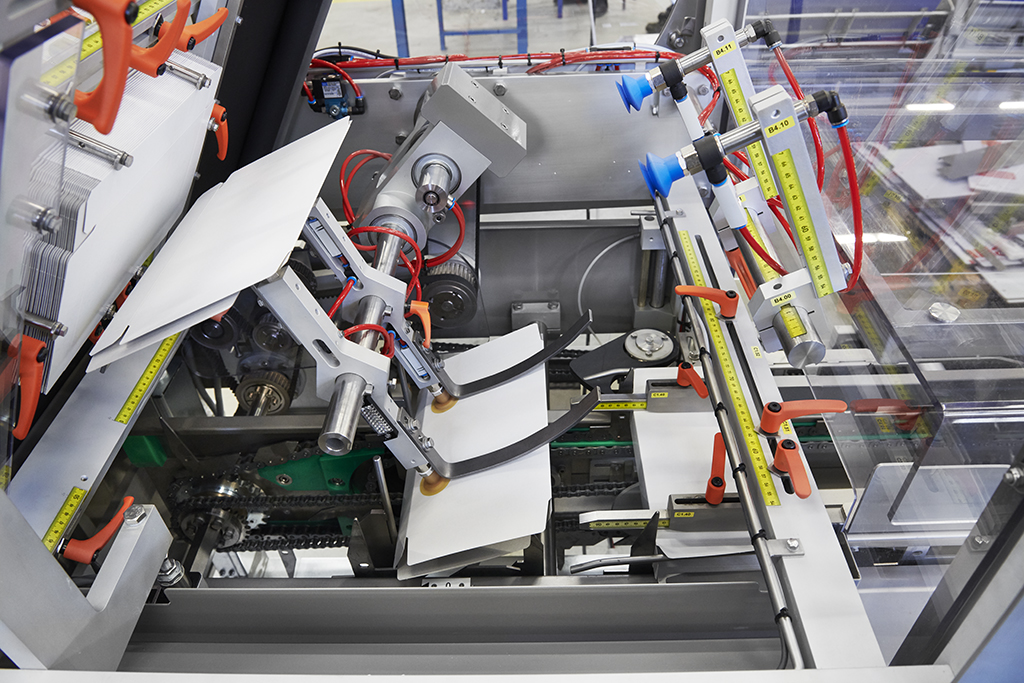

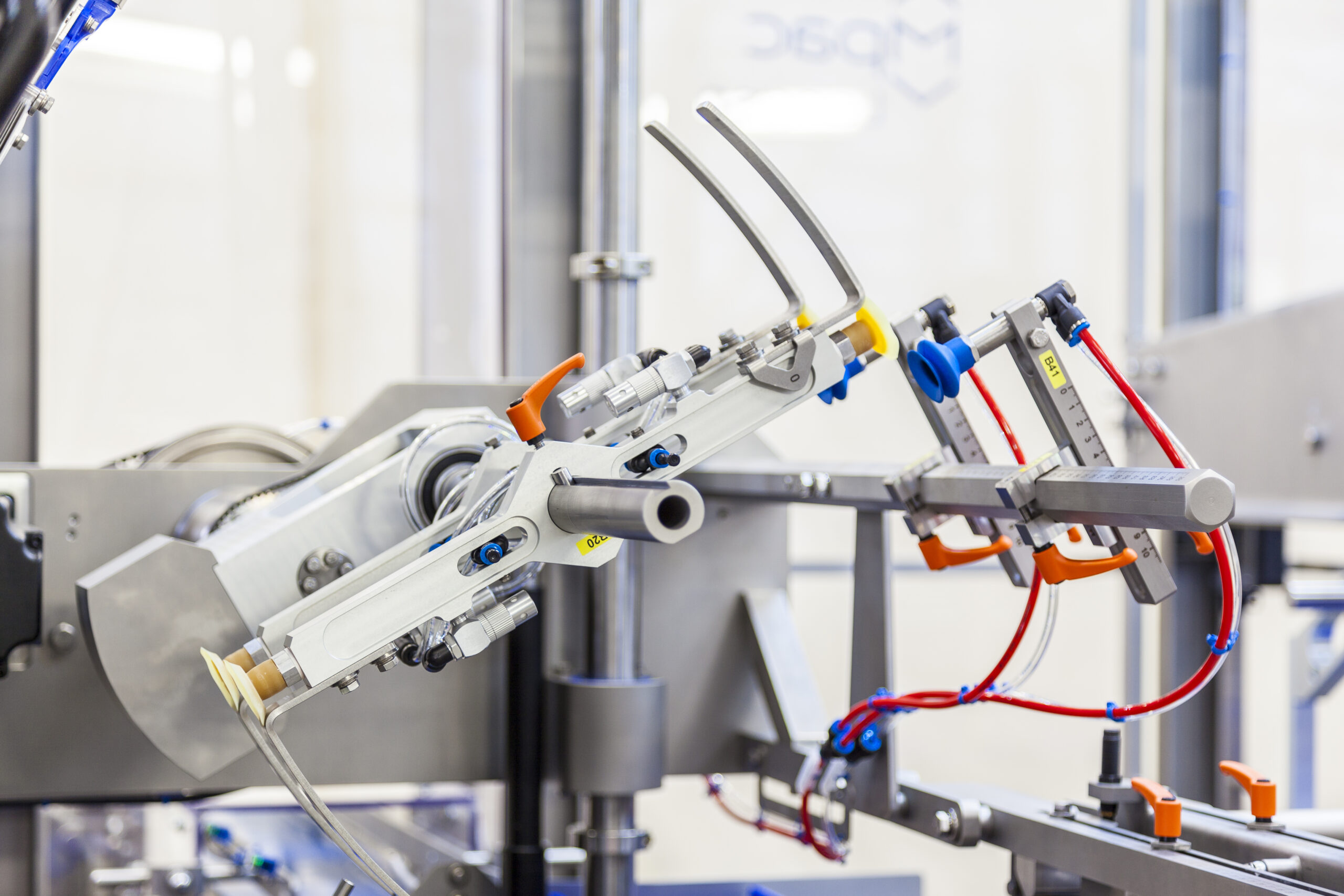

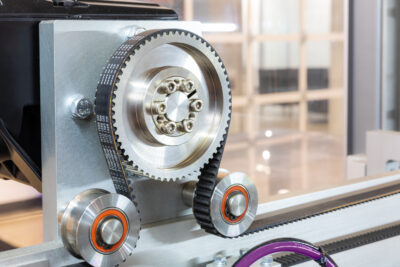

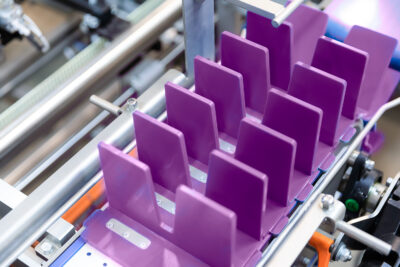

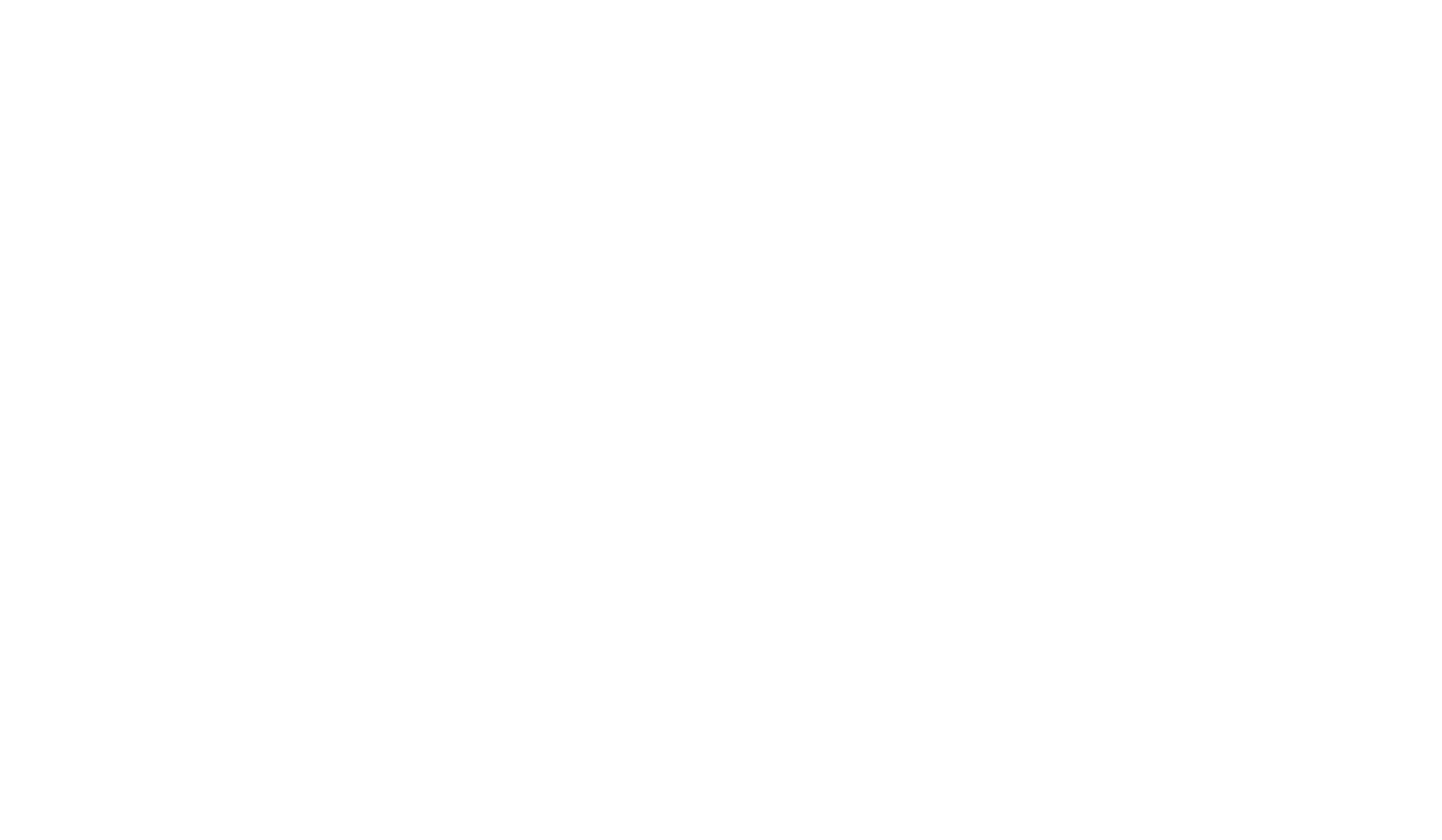

Luckily, our flexible assembly platforms rapidly adapt to keep your lines flowing. And naturally, they’re incredibly hygienic and easy to maintain, with a transparent glass-panel design.

Our ostomy product cartoning capabilities include:

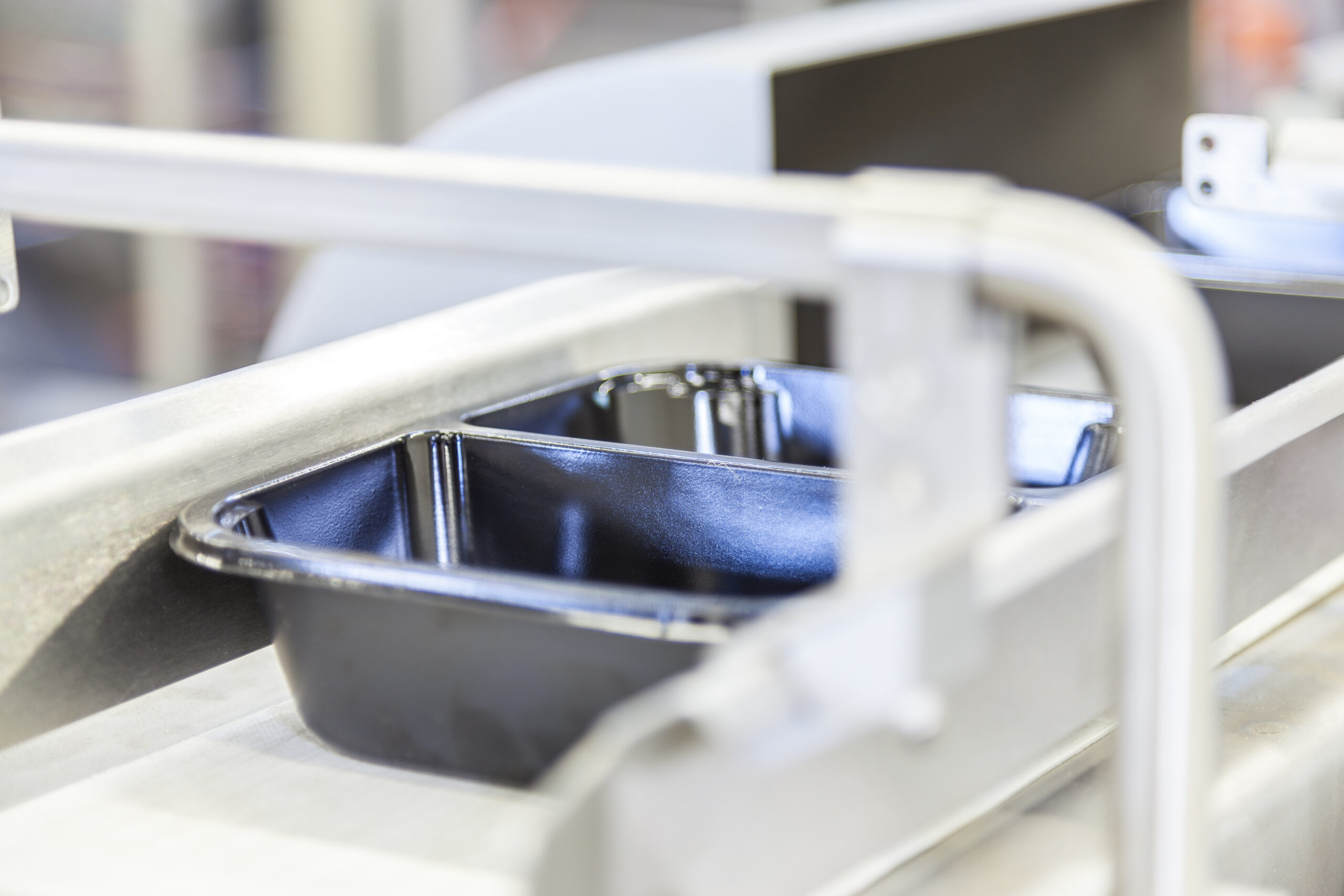

> One-piece ostomy system: the skin barrier and pouch are manufactured as one system and cannot be separated, offering discretion and flexibility for a variety of situations like exercise and other physical activities.

> Two-piece ostomy system: the skin barrier and pouch are manufactured separately and can be applied to the body individually or together. This allows for easy removal of the pouch without removing the skin barrier.

> Tap and outlet pouches: providing security and comfort throughout the day.

Our Approach

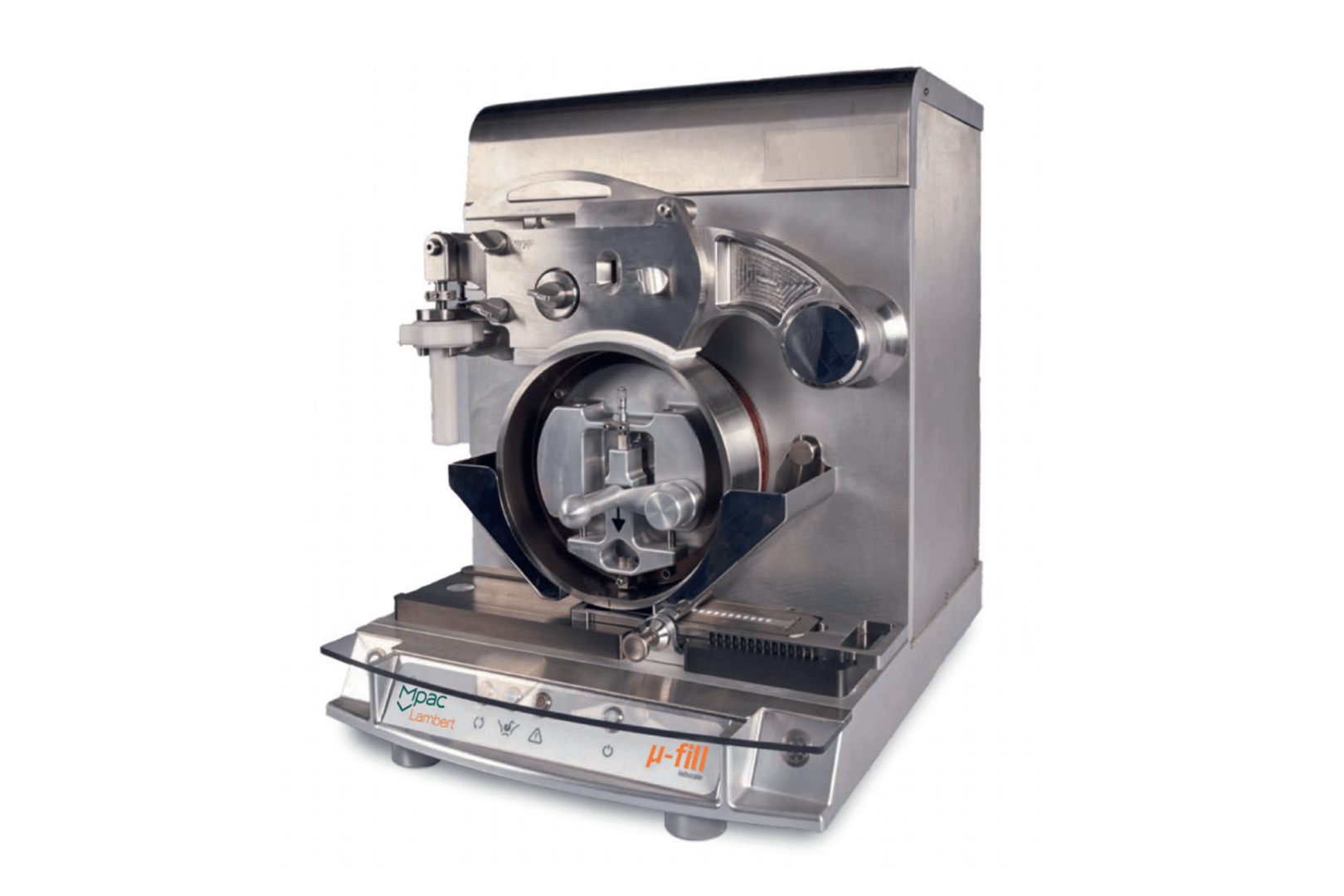

Forget what you know about the limits of ostomy product cartoning. Whether you require standard or tailored solution, our industry-leading machines are capable of exceeding your expectations.

Mpac Group’s automation machine experts will take the time to listen to your bespoke needs and advise you on the best assembly platform for your ostomy product production line. We go above and beyond to ensure our machines are robust, stable and scalable to give you the most cost-effective packing solution on the market with the highest equipment efficiency.

Contact our world-leading engineers

Our world-class engineers support every stage of your evolution. To discuss your requirements with a member of our friendly team, get in touch by filling out the enquiry form opposite.