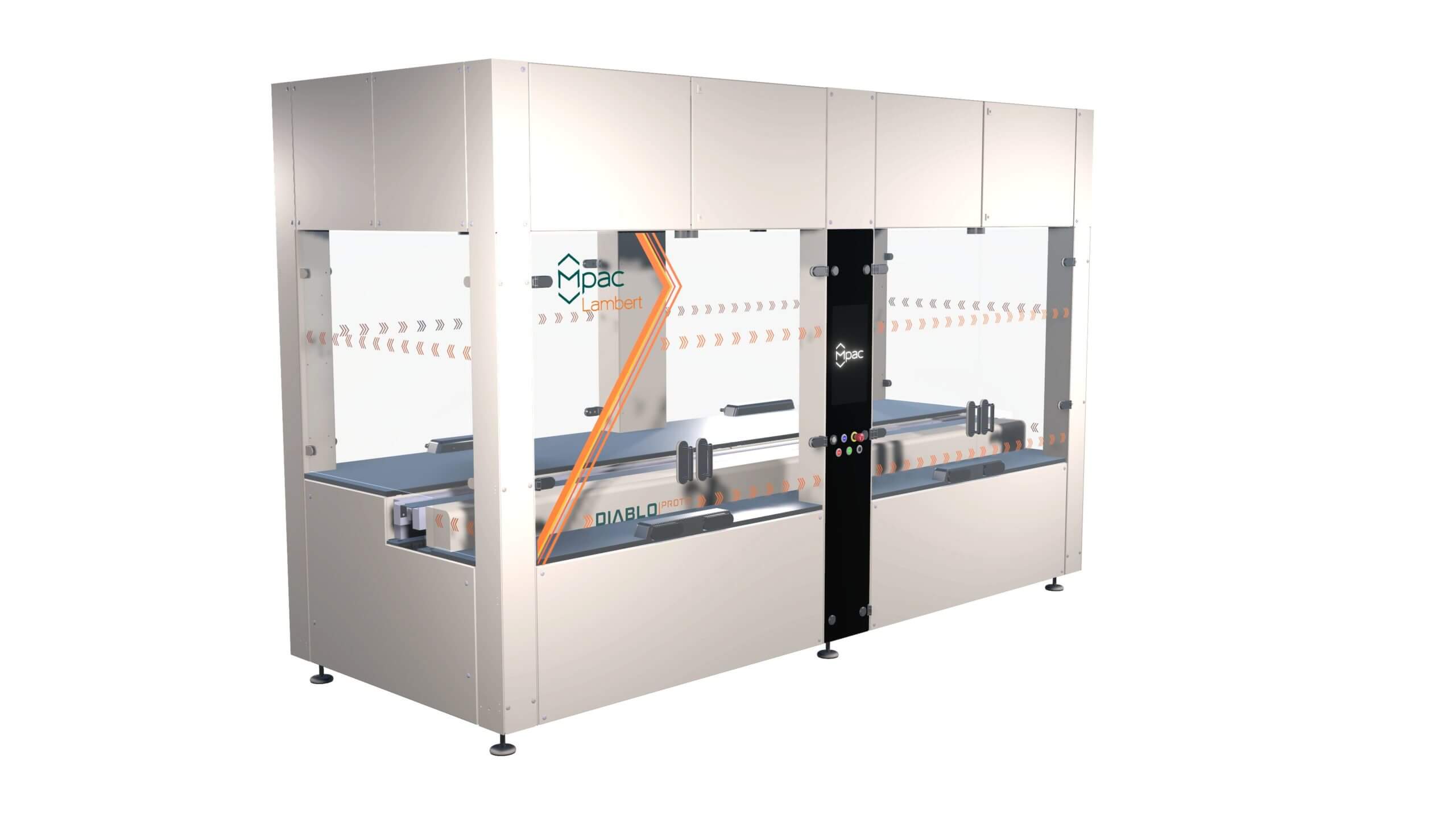

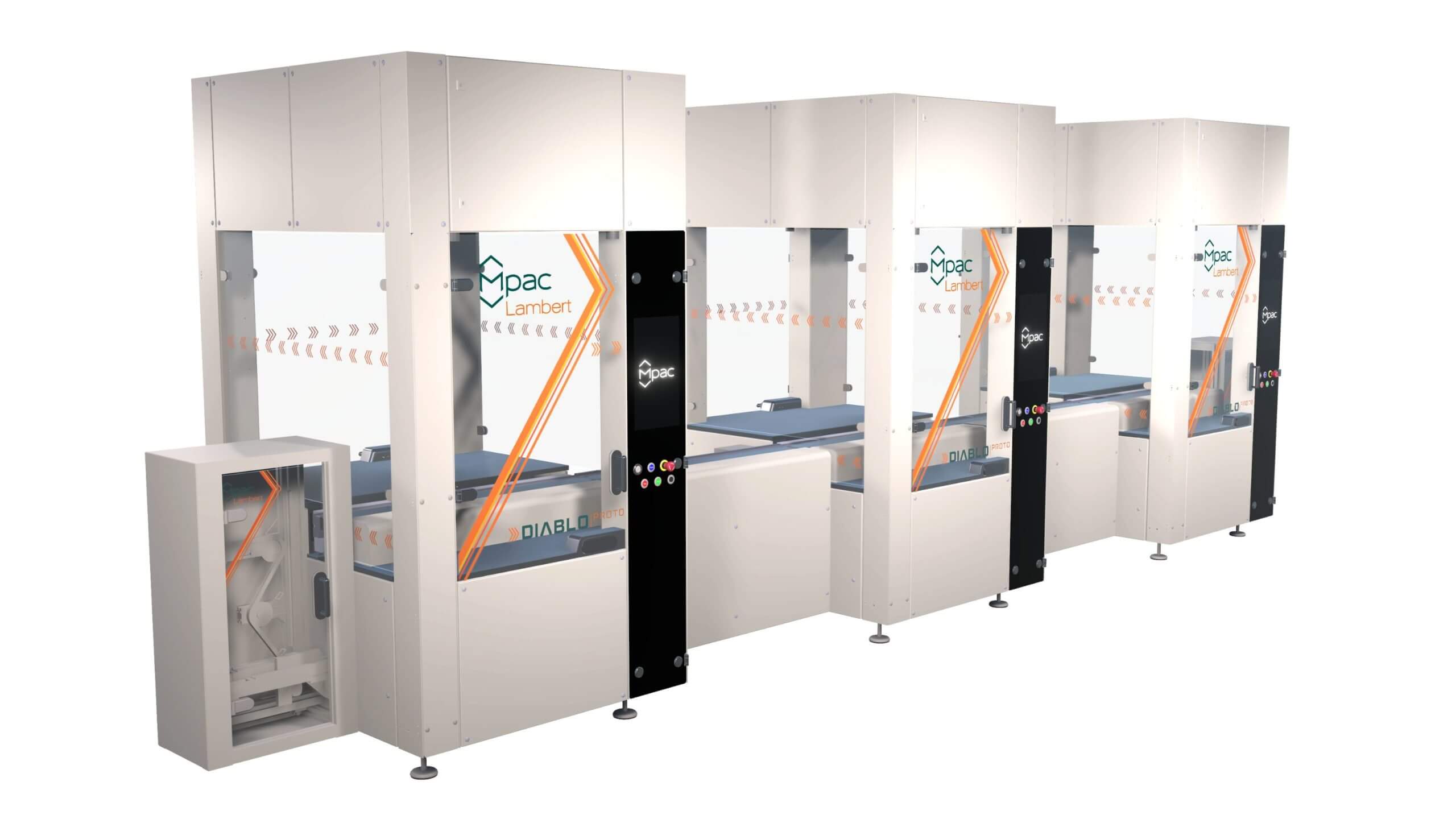

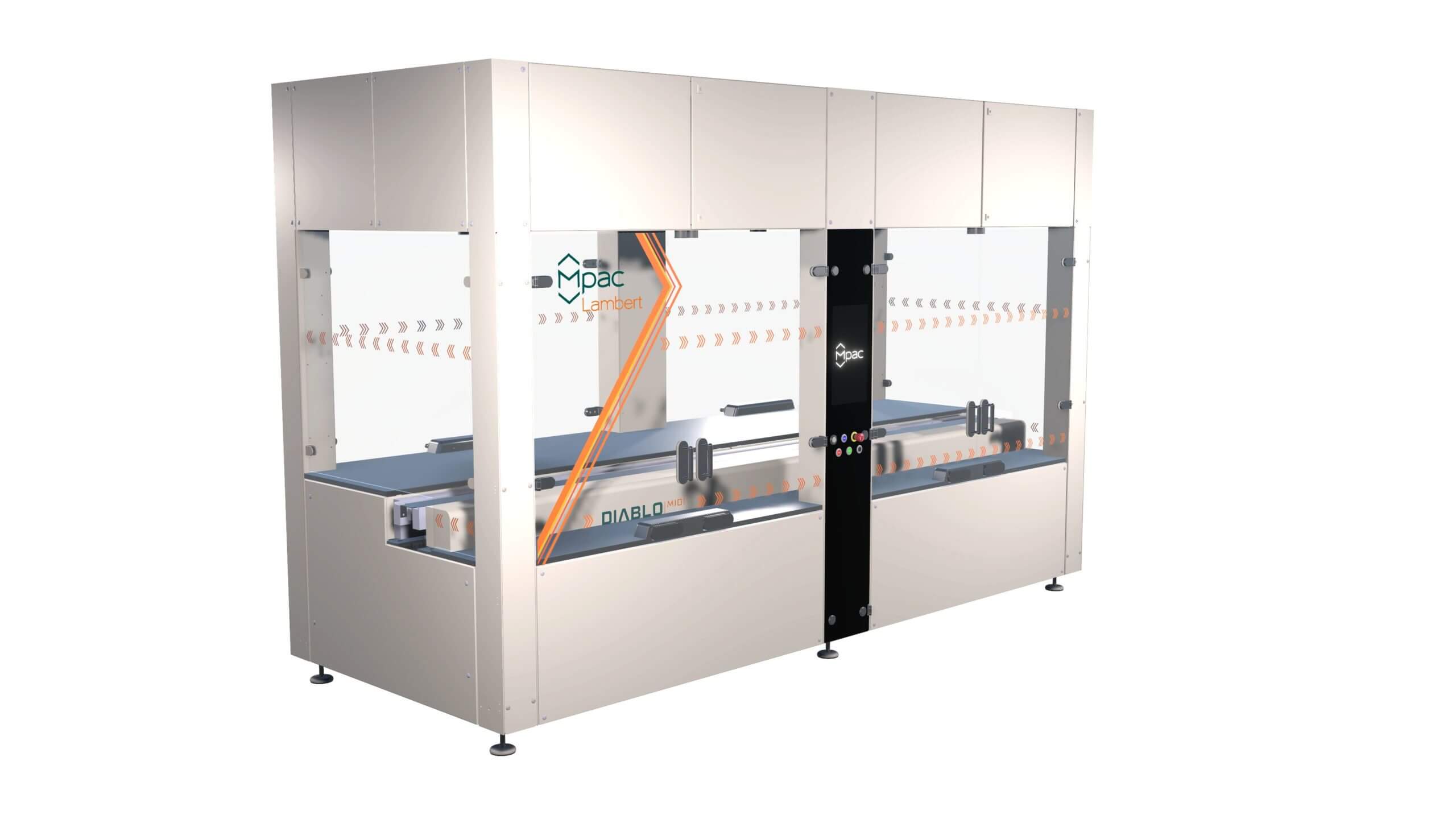

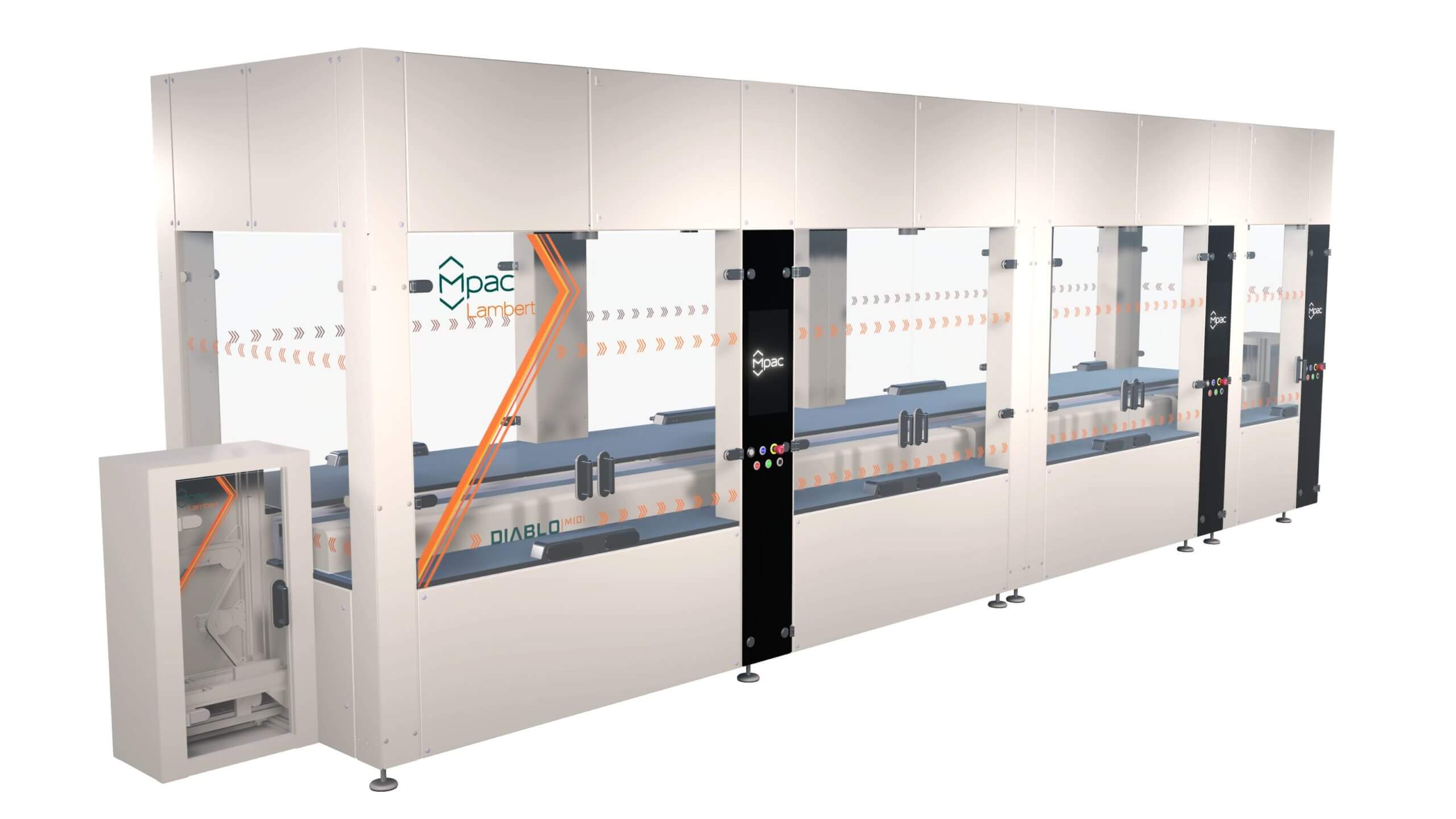

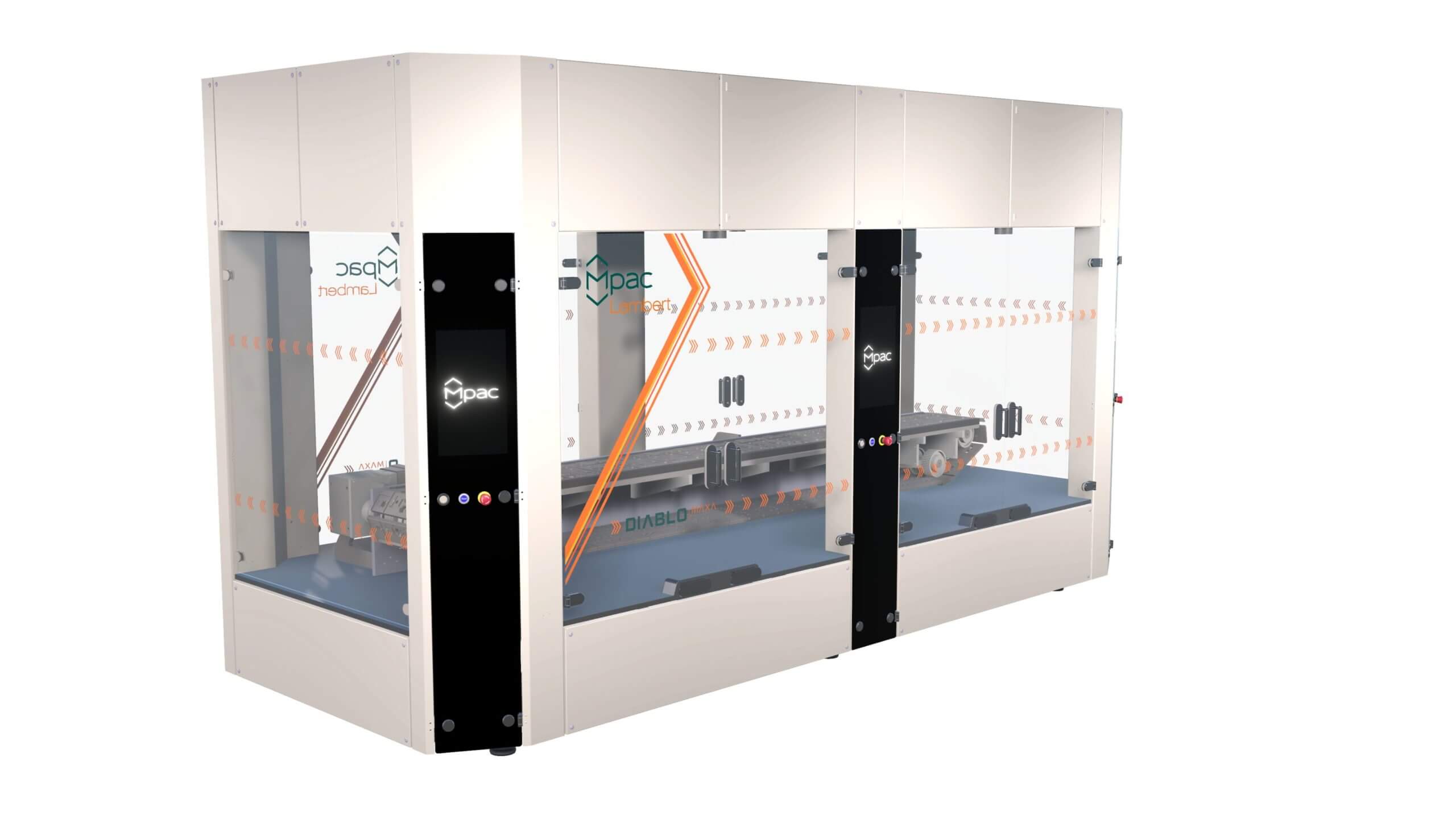

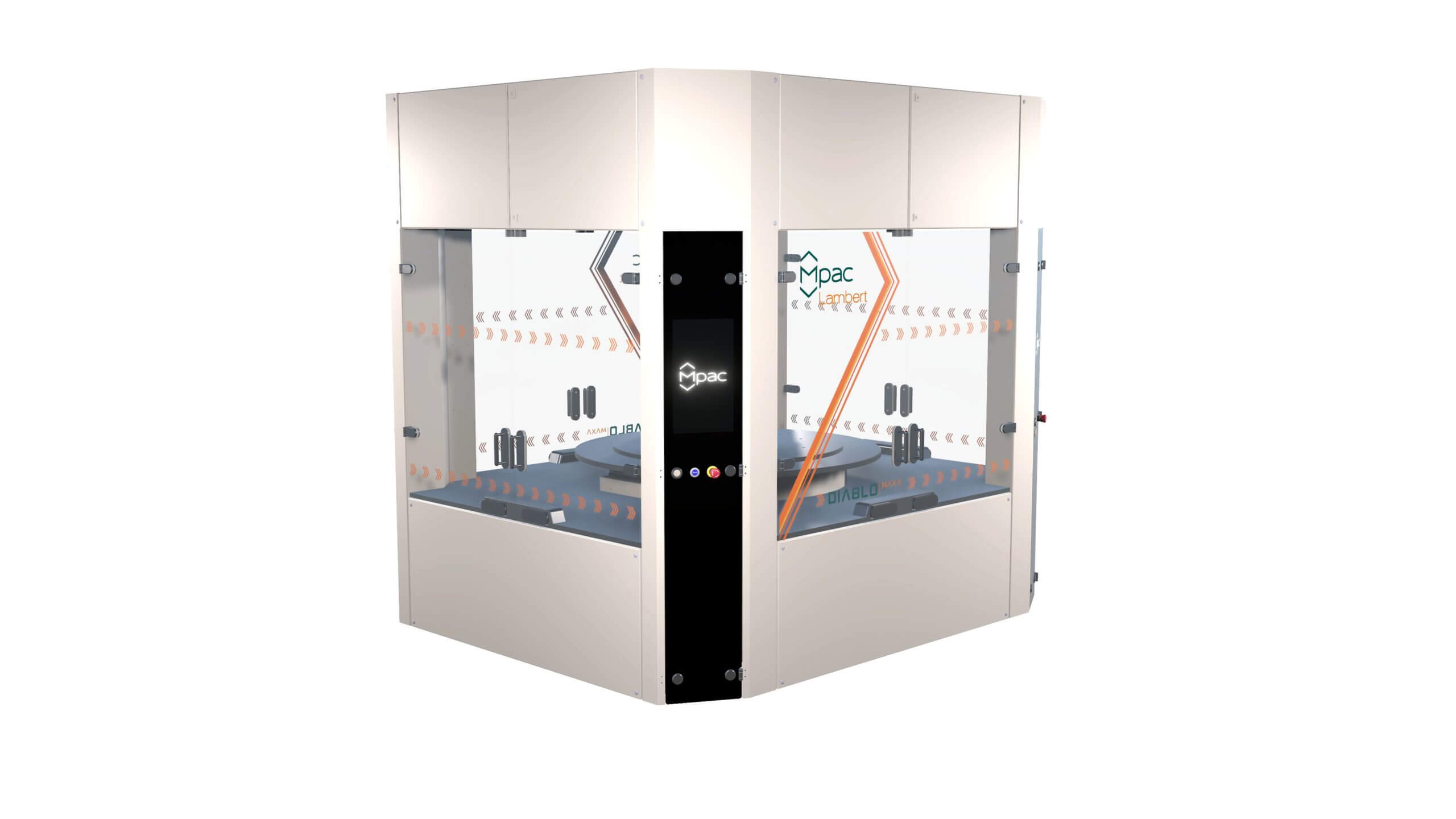

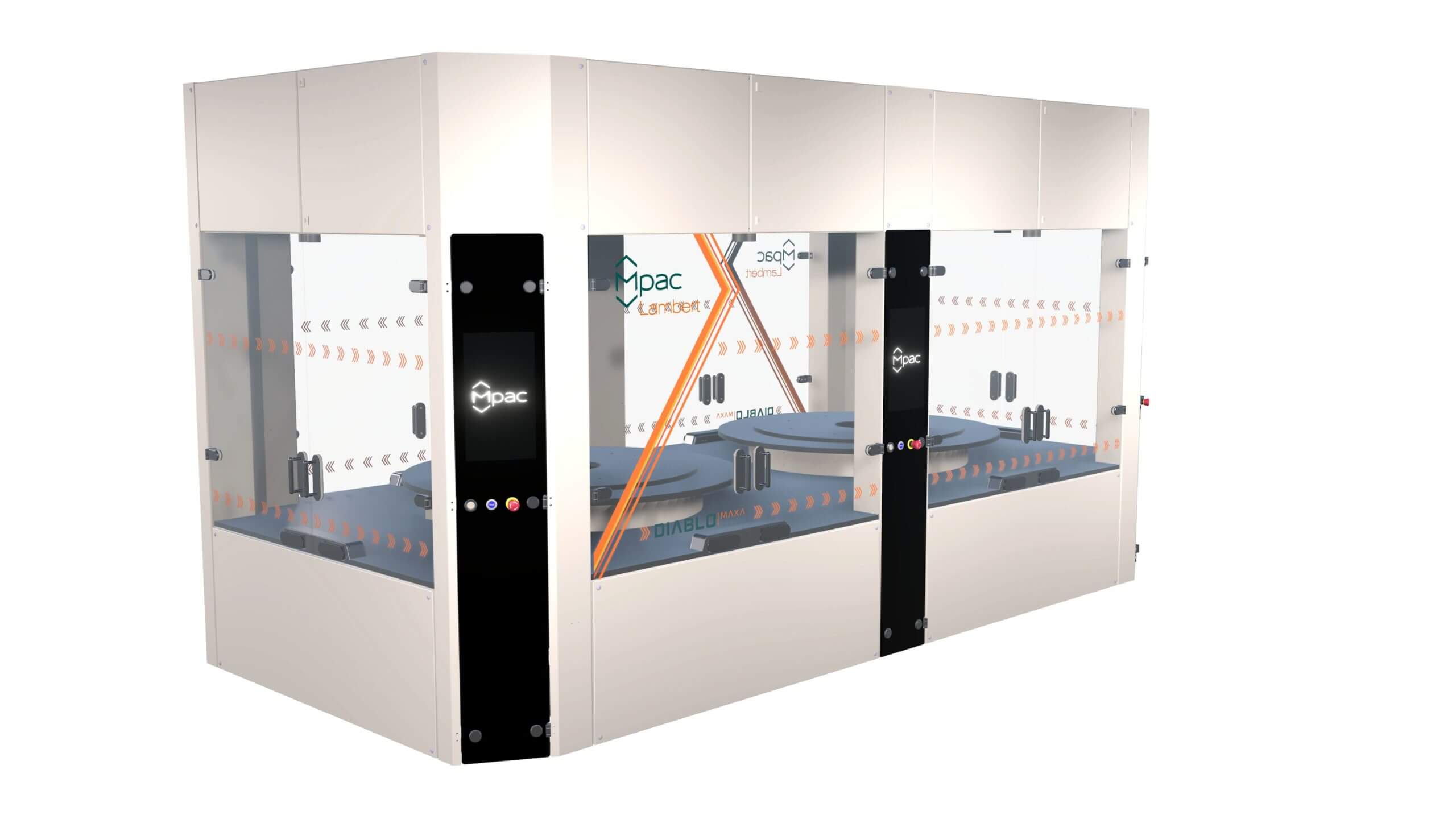

Flexible assembly machine platform

When you’re looking for assembly machine with added flexibility, the Lambert Diablo range delivers. Whether, you’re making 50 products, or 50 million, we have a platform to fit.

Each platform is a base that includes control panels, transportation, cable runs, guarding, HMI and frame/structural supports. In as little as 12 weeks*, we can configure machinery to match what you need at a fraction of the lead time for first of a kind (FOAK) systems.

It’s a solution designed with a specific goal in mind: getting your products to market in record speed. The Lambert Diablo’s standardised building elements, module-mounting and pneumatic layout make it faster to build, easier to maintain, and more cost effective than conventional solutions on the market. All of this, whilst providing you with a solid foundation for scaling up as your business grows.

*Standard Proto Cell

Request a specification sheet

Features and benefits

- Shorter lead times

- Lower energy use

- Higher reliability

- World-class OEE

- Rugged, modular and robust construction

- Ergonomic design

- Pre-configured screens and menus for easy operation

- Reduced total cost of ownership

- No fault forward

- Remote diagnosis

Need something more bespoke?

We provide special purpose machinery and solve problems that others can’t. Our innovative, bespoke solutions are unique to your specific needs and developed from the ground up.

We also offer a Design for Manufacture service, where our world-class engineers work closely with you to improve your product’s readiness for automation. That way, you can get your products to market with complete confidence.

To discuss your specific requirements, contact us.