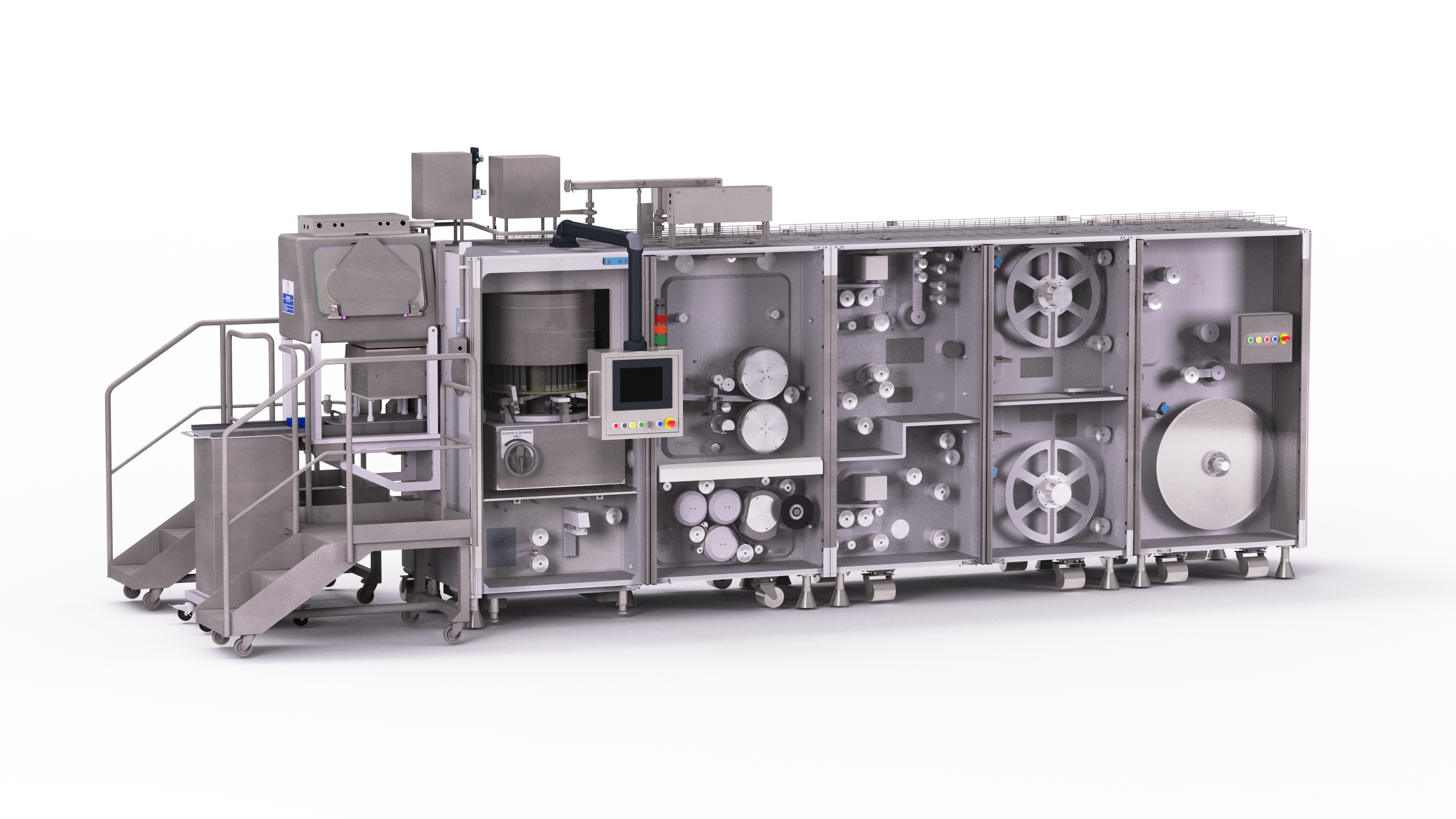

Forming, Filling & Sealing of DPI Blister Strips

Mpac Lambert’s high-precision, micro-dosing, Dry Powder Inhaler (DPI) Blister Filling System, is specifically designed to handle Active Pharmaceutical Ingredient (API) combinations using excipient blended powders such as lactose with a magnesium stearate additive. These combinations assist powder flow, dispersion and stability of the drug, to improve it’s delivery to the lungs used to relieve symptoms of Chronic Obstructive Pulmonary Disease (COPD) & asthma.

Mpac Lambert’s high-precision, micro-dosing, Dry Powder Inhaler (DPI) Blister Filling System, is specifically designed to handle Active Pharmaceutical Ingredient (API) combinations using excipient blended powders such as lactose with a magnesium stearate additive. These combinations assist powder flow, dispersion and stability of the drug, to improve it’s delivery to the lungs used to relieve symptoms of Chronic Obstructive Pulmonary Disease (COPD) & asthma.

Control & Consistency

API combinations need controlled handling. If the powders coat the surface of the blister strip they prevent effective sealing. Our filling process directly and precisely doses each individual pocket in the blister strip with powder, leaving the surface clean and ensuring the integrity of the seal.

The system is designed to maintain tension and accuracy of the strip position to ensure clean and correct dosing of powder into the blister strip, effective sealing against leakage and clear printing for batch tracking and quality control.

Scalable Solutions

Our systems can be found in productions lines for DPI inhalers across the world and our long-term success in the industry has been achieved by offering consistently effective and scalable automation solutions. Automation for R&D scale validation, micro testing & analysis, strip handling and cutting, coiling and inserting strips, up to full assembly of the DPI device, can all be designed to your production line specification.

Discover more by downloading the brochure.

Why market-leading DPI manufacturers choose Mpac:

- Forming, filling and sealing of dry powder blister strips cleanly and accurately

- From R&D validation scale automation to full commercial production lines

- Inspection and controls designed to ensure consistency of product

- Proven design and installation of machines from validation stage to commercial production

- Scalable solutions that grow with your business

You might also be interested in:

- The Lambert μ-check: Pharmaceutical powder checkweighing made easy

- The Lambert μ-fill labscale: A semi-automated benchtop system for dosing powder into preformed blisters

- Whole line integration: The Mpac Group offers full line solutions from product assembly, handling and vision systems to tray forming, cartoning and palletising

- Lifecycle services: Working with you to achieve your production goals through connectivity, productivity and sustainability, with in-person, remote and digital services